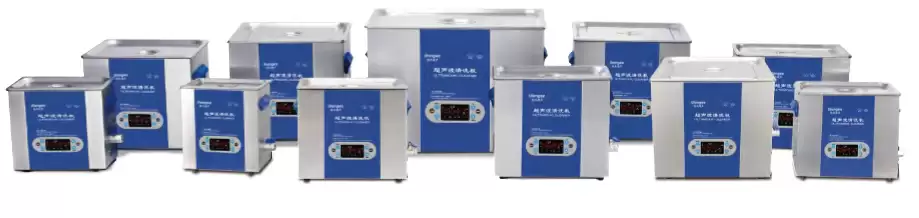

Ultrasonic Cleaner BJR1F5 (BULC-605)

Lcd Digital Ultrasonic Cleaner- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BJR1F5 |

| Capacity (L) | 11 |

| Frequency Working (Khz) | 39±1.5 |

| Ultrasonic Power(W) | 240 |

| Heating Power(W) | 300 |

| Timing time(mins) | 10s-100min |

| Temperature Range(°C) | 20-80 |

| Cover | YES |

| Valve Drain | YES |

| Working Basket | optional |

| Inner tank Dimension (mm) | 300X240X150 |

| Packing size (mm) | 379X265X292 |

| Gross Weight (Kg) | 8.5 |

Description

In dental practice,dental instruments such as forceps,chisels,scalpels, anddrills must be thoroughly cleaned before disinfection.Before sterilization, cleaning is performed using ultrasound. By using ultrasonic clinic instruments developed there is no problem with removing alginate the impression tray and removing gypsum from the dental mold.

products have prevent oxidation,temperature protection function to prevent dry burning and time adjustment and power adjustment functions to meet your different cleaning needs.

In the laboratory, ultrasound also has many different applications,such as cleaning dissolution,homogenization,degassing,and emulsification. ultrasonic cleaning,equipment has been optimized for typical laboratory use,providing more problem-solving solutions. Our ultrasonic cleaner is used for strong cleaning of glass instruments,grinding joints, burettes, pipettes, test tube racks,and other items. Some difficult to reach areas can also be cleaned.Our ultrasonic machine is suitable for laboratory applications,such as HPLC solvent degassing, sample digestion,and emulsification processes. The circular ultrasonic cleaner developed emulsification processes.The circular ultrasonic cleaner developed specifically for the laboratory has a very uniform sound field distribution and a cleaning agent with an acidic to alkaline pH value, which improves the product range.

Nozzles, hot beds, and other components are easily consumable.To ensure optimal performance of consumable.To ensure optimal performance of 3D printers, it is necessary to clean spare parts.Compared to traditional methods,using ultrasonic cleaning methods,using ultrasonic cleaning can greatly reduce consumables and save labor.Non destructive workpieces fast cleaning. Suitable for components such as nozzles,movements, triangular flat seats,

aluminum alloy shells,stainless steel wire wheels, etc.,as well as frames for guide

rods, oil pumps,pump accessories,printers, and printing models.

Optical components have many different components. and due their characteristic they are widely used in various fields ultrasonic cleaner and cleaning systems are used for the production of micro,infrared, or precision optical devices,as well as the manufacturing of eyewear lenses, and are used for cleaning glasses in many well-known eyewear stores.

When producing various optical devices,our Langee experts and customers work together to develop the best cleaning process tailored to different optical material components,using a specially developed modular production line with separate system solutions and material compatible cleaning agents.

The application of metals, mixed metals, and specific substrates is very extensive and is applied in various industries.Machines and components used in the manufacturing industry must also be cleaned regularly to ensure stable performance and smooth operation in the best possible way. Ultrasonic cleaning system plays an important role here, and engineers work with customers to develop the best cleaning process. Each machine component,tool,and auxiliary tool is professionally cleaned, rinsed, and dried in a modular or customer specific ultrasonic cleaning system without residue.

Features

LCD display screen

Degassing

Prevent dry bum

Power adjustable

1. LCD display and control,simple operation;

2. One-key degassing can quickly remove air in water, and the ultrasonic cleaning effect is better;

3. Independently developed MCU-sweep ultrasonic generator drive, uniform and strong ultrasonic effect;

4. Independently developed industrial high Q value transducer with high ultrasonic conversion efficiency and long service life;

5. Power adjustment function,can meet different cleaning requirements;

6. Imported high strength glue, seedless nail bonding process, higher ultrasonic conversion efficiency:

7. Digital timing,cleaning time 10s-100min and digital heating control, temperature 20-80°C arbitrary setting;

8. The inner groove adopts imported SUS304,1. 0mm stainless steel stamping, ultrasonic exchange effect is better, longer service life;

9. The washing basket is made of high quality 304 stainless steel mesh welding, surface electrolytic polishing treatment;

10. The shell is made of high quality stainless steel,with better anti corrosion effect.