Laboratory Vertical Autoclave BEO1D4 (BAVT-401-B)

Vertical Autoclave, Auto Water Fill- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BEO1D4 |

| Capacity(L) | 60 |

| Dimension(L*W*H)(mm) | 644x831x980 |

| Chamber dimension(Dia*H)(mm) | Φ390x505 |

| Rated power(W) | 2900 |

| SUS 304 Basket(Dia*H)(mm) | (Φ 370x190) x2 |

| Power requirement | 220V±10% 16A 50HZ/60HZ |

| Temperature display accuracy | 0.1°C |

| Working environment | 5°C~40°C relative humidity ≤85% |

| Chamber material | SUS304 stainless steel |

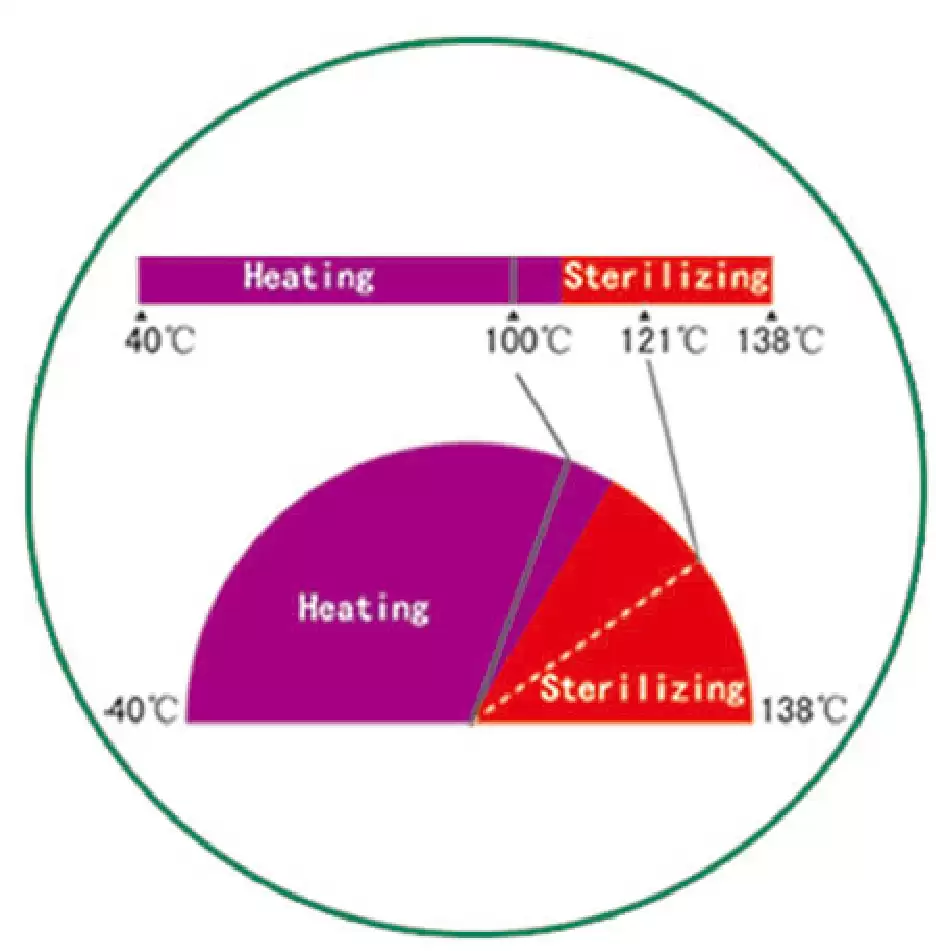

| Sterilization temp. range | 105°C~138°C |

| Sterilization time range | 1~6000 min |

| Melting temp. range | 60°C~115°C |

| Melting time | 1~6000 min |

| Warming temp | 45°C~79°C |

| Warming time | 1~9999 min |

| Drying | Drying time: 1~300 min |

| Cooling lock OPEN temp. range | 40°C~99°C for solid,waste,agar,self-defined |

| Sterilization mode | Liquid,Liquid with warming,solid,Wrapped instrument,Fabric,Rubber,Fast,Waste,Agar,Self-defined |

| Program number saved | 60 programs |

| Exhaust speed control | Fully automatic internal discharging with 6 levels choice |

| Lid open way | Flip open(up and down) |

| Water tank | 1 water storage tank |

| Appointment timer range | (Auto start up appointment) 0 ~ 15 days |

| Pressure gauge range | -0.1~0.5MPa |

| Pressure valve set pressure | 0.29 Mpa |

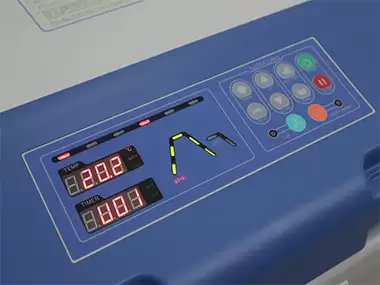

| Controller | "Inspiration" smart microcomputer controller |

| Safety Device | Eight column evenly distributed interlock device, electric double inter lock,lid closing checking,dry scorch protection,safety valve,water level sensor,over temperature/pressure protection,temperature/pressure monitor, electricity safety(over current/short circuit/leakage),cooling lock,anti-scald lid and bench corner,automatic troubleshooting |

| Biosafety function | Option for 0.2μm biosafety filter |

Features

Safety:1. Humanized design:

The lid and bench corners are covered with insulation to avoid getting scalded.

2. Interlocking device:

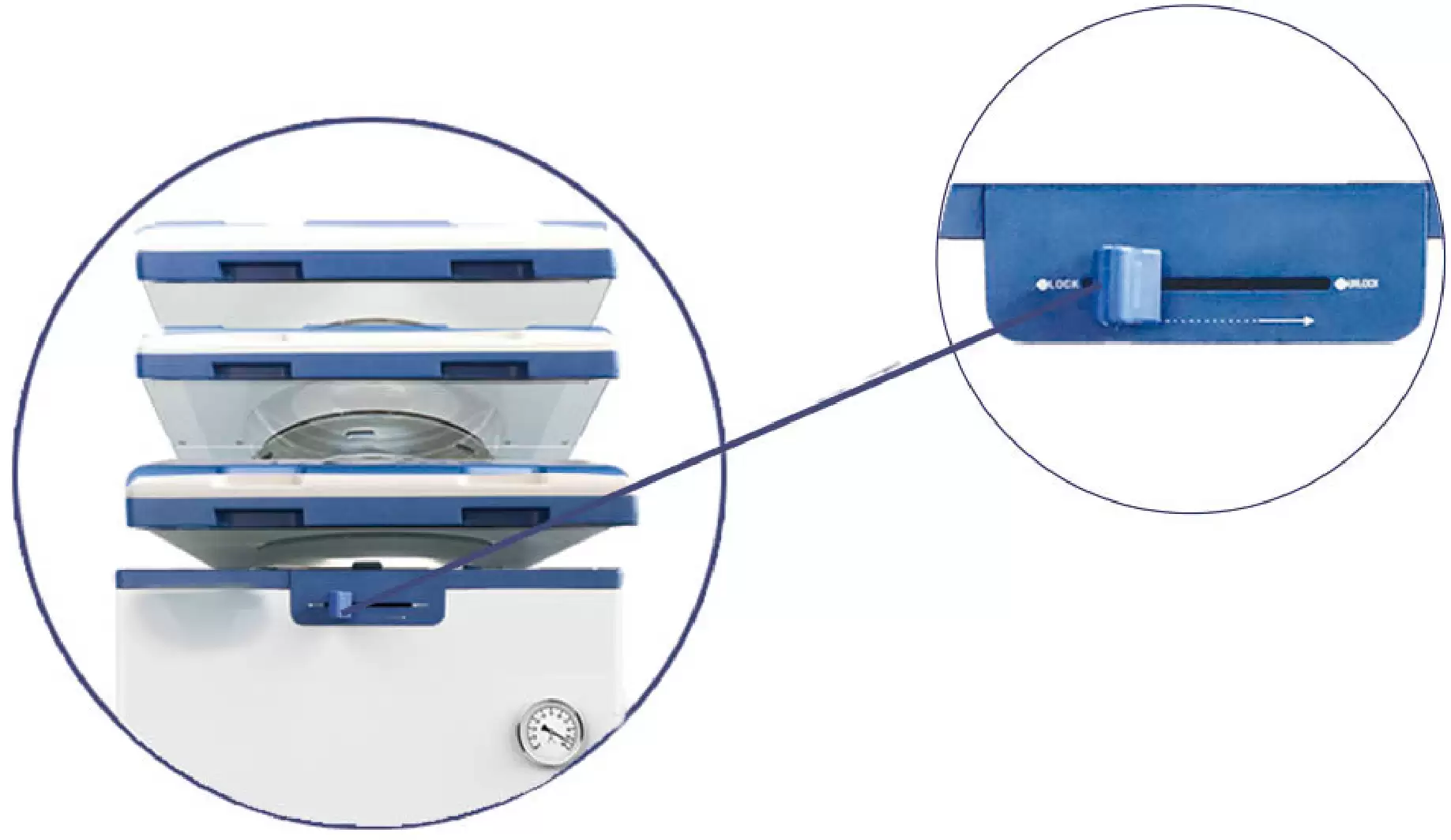

The exclusive patented "eight column evenly distributed" interlock device is safer and more reliable than ordinary interlocking devices.

3. Lid closing checking:

The machine cannot start if the lid is not locking well by checking mechanically and electrically.

4. Real time monitor:

The system will monitor the lid locking, pressure, and temperature status on a real-time basis to guarantee the safe and successful operation of the autoclave.

5. Cooling lock OPEN temperature:

Each program can set different lid OPEN temperatures, especially for liquid programs, so as to prevent users from opening the lid and causing burns when the articles are still in a high temperature state.

6. Triple protection for lack of water:

The bottom of the sterilization chamber is equipped with three different dry burning protection devices: liquid expansion type, copper temperature sensing type, and electric ion type (water level sensor), to avoid misjudgment caused by a single method.

7. Double protection for over pressure:

Mechanical pressure gauge and electric sensing system-once pressure is abnormal, the system will cut power, release the pressure, and send out an alarm.

8. Auto troubleshooting:

The system will monitor the working status, and will cut the power, send out an alarm, and report the error information once any abnormal situation is detected.

9. Safety test function:

Regular testing of system security and safety protection measures is possible.

10. Electrical protection:

Equipped with a highly sensitive electrical protection system, effectively providing leakage protection.

Characteristics:

1. Smart microcomputer control

"Inspiration"high speed microcomputer control,not only to monitor and control the whole process, but also to update the function in the future.

2. Program Memory storage system

Users can set their own program, and save it in the system.

3. Calibration interface

Offer temp.and pressure interface, together with the 3Q adapter joints, can insert max 15 sensors one time to do the calibration work

4. Saturated steam monitoring

The system automatically monitors the purge out of cold air to ensure the pure steam environment

5. Humanized permission management

The management of the autoclave 1s classified into 3 levels, user-administrator- engineer, to ensure proper usage.

6. Agar program

Can heat up, melt, warm the agar or used as chamber preheating function

7. Waste program

Special waste program to sterilize the waste thoroughly

8. Auto start up appointment

Can make an appointment in 0-15 days

9. Option for all model

Hepa filter (0.2um,efficiency 99.90%) for exhaust+one steam condenser

10. SUS316L Stainless Steel(Option)

Stronger corrosion, longer service life,and greater pressure resistance

11. LCD/USB/APP/Smart Management System (Optional)

LCD: 5-inch screen displays information in text.

USB: Enables storing and transferring sterilization data.

APP: Remote management app (available only in China).

Smart System: Linked with the LIMIS/SCADA system (only in China).

12. Condenser(Option)

Equipped with a professional condenser, the steam generated during the sterilization process is converted into water through the condenser, achieving zero discharge of water vapor/mist.

13. Biosafety function

Use a 0.2 μm PTFE filter (efficiency 99.90%) packed in a housing to ensure that no biohazard aerosols, microorganisms and viruses are passing out through the filter during exhausting, so as to ensure the biology safety of the lab.

14. Monitor of exhaust filter

Exhaust filter 1s put inside a pressure resistant housing (stainless steel material) with an extra PT100 temperature sensor to monitor the temperature, so as to make sure the filter and housing are also being sterilized thoroughly, and will not lead to secondary biohazard pollution.

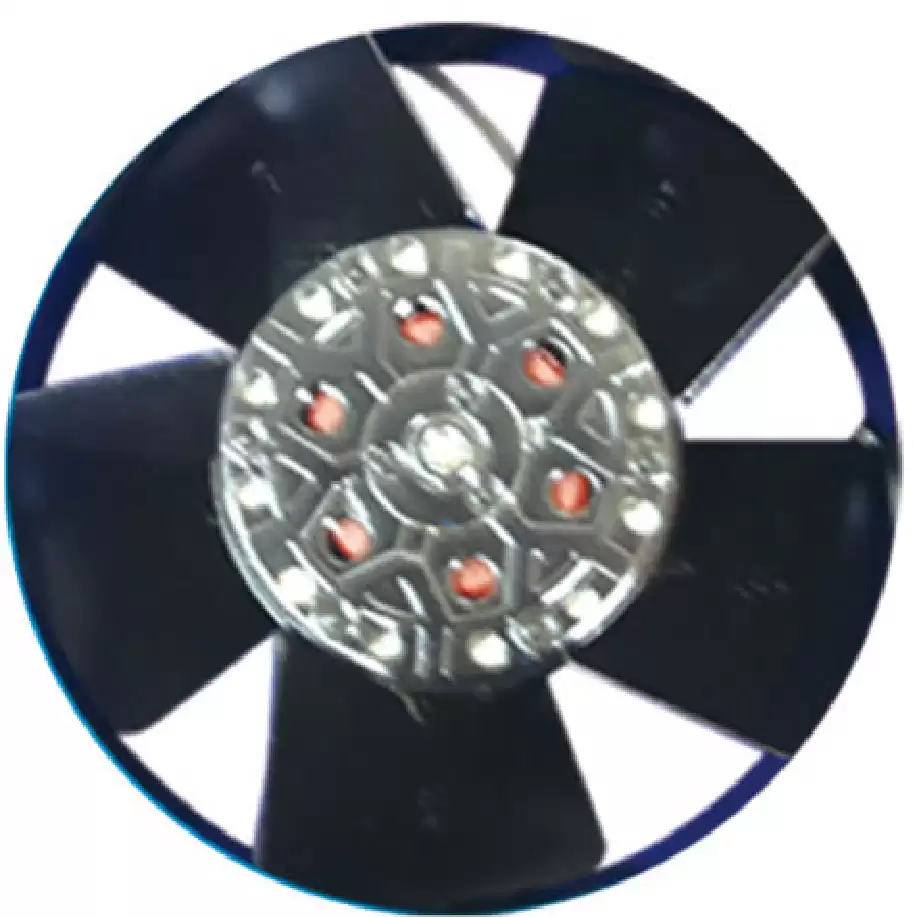

Fast cooling fan

Fan to shorten the whole cycle Standard with fast cooling

Highest working temp.138°C

6 levels of exhaust speed control

After sterilization,you can choose different exhaust speed, and you can adjust it freely at any time of exhausting

Up and down flip open ,vertical chamber ; One move by one hand can easily open and close

Preset diverse programs

Flow chart to show the process,press DATA at any time can check the current program setting

More Info

1. Auto water fillEquipped with automatic water feeding function, standard is with 28L water tank at the back to store water, option is direct water supply by pipe connection from water source while manufacturing.

2. LCD/USB/APP/Smart Management System (Optional)

LCD: 5-inch screen displays information in text.

USB: Enables storing and transferring sterilization data.

APP: Remote management app

Smart System: Linked with the LIMIS/SCADA system.

3. Auto Drainage (optional)/Auto Cleaning

Includes a water pump. Drainage can be initiated by pressing a button or set for timed automatic drainage. Automatic cleaning can be scheduled regularly or after each sterilization cycle.

Accessories For Purchase

| Images | Name | Description |

| Micro printer | To print temp. time and FO value Printing set:printer+digital pressure sensor:can print temp.and pressure in data and flowchart way |

| Digital pressure sensor | Printing set:printer+digital pressure sensor:can print temp.and pressure in data and flowchart way |

| Load thermometer | Floating PT100 sensor |

| Tray | |

| Stainless steel bucket | |

| IQ/OQ/PQ (3Q)adapter joint | |

| Adjust foot |