Forced Convection Oven BGI2G6 (BOFC-5501)

Ovens, Forced Air Oven- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BGI2G6 |

| Type | LCD Controller |

| Capacity (L) | 35L |

| Temp Range | RT+10°C - 200°C (MAX 300°C) |

| Display Resolution | 0.1°C |

| Uniformity at 100°C | ±2.0°C |

| Heated to 100°C | 25mins |

| Standard Max number of shelves | 2 (5) |

| Max load per shelf | 20Kg |

| NW | 43Kg |

| Timing Range | 1 - 5999mins |

| Interior Dimension WxDxH (mm) | 320x350x320 |

| Exterior Dimension WxDxH (mm) | 610x550x540 |

| Electrical Requirement | AC220V 50Hz |

| Power Consumption | 900W |

Description

Natural Convection Oven:The high temperature drying oven provides a stable high temperature environment through precise temperature control, which enables drying and disinfection of glassware, solid objects, solid materials, process equipment, etc. In this type of oven the temperature distribution is based on warm air moving upwards (see diagram). There is no fan that actively distributes the air inside the chamber. The benefit of this technology is very low air turbulences for gentle drying and heating.

Features

Humanized design:With reservation and timing functions, there is no need to wait, which effectively improves the efficiency of the experiment.

Available in Chinese and English menus to meet different language needs, with degree C conversion.

The height of the shelf is adjustable to meet different cultivation needs.

Professional stacking foot design, the machine can be stacked, saving lab space and improving the use efficiency (same specification).

Safety:

Protection on instruments: Comply international standard secondary temp limiting alarm system, when the heating is out of control or exceeds the maximum limit temperature, the heating is automatically cut off with sound and light alarm, ensure operating is safe without any accident.

Protection on key components: Key components are equipped with over-current, over-temperature, overload and other safety protection to prevent accident.

Protection on samples: When the temperature inside the box is higher or lower than the set temperature, the alarm will start to cut off the heater, with sound and light alarm to remind the operator to protect the sample from normal test without accident.

Protection on operator: The cabinet and door are specially insulated to make the surface temperature of the cabinet low, ensuring the operator's safety and no accidents.

Breakdown message provided: When the instrument breakdown, the message will shown on the screen to help operator clearly check.

Convenient data processing:

The touch screen type standard with a USB interface, which can record the change status of the temperature parameters.

The LCD screen is option for USB interface.

It can be equipped with RS232 data interface, which can realize remote control of the machine through software (option).

RS-232 and USB can be selected one of them.

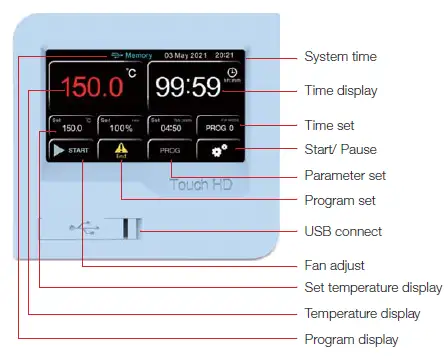

Colorful intelligent touch screen:

Advanced Color Intelligent Touch Screen Control:

1. 4.3 inch touch screen, intelligent touch control, real-time display of parameters, simple and

convenient operation.

2. Quick setting of temperature, time and other parameters can be carried out.

3. It has the function of program setting. It can be programmed in 7segments, 63 steps, 9 steps

and 1-99 hours and 59 minutes per segment.

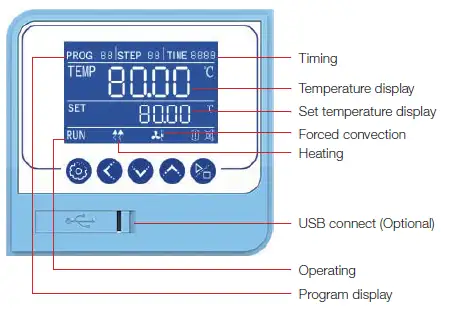

Professional LCD Controller:

1. Intelligent program control with high brightness LCD screen, button operation and real-time

display of parameters.

2. Quick setting of temperature, time and other parameters can be carried out.

3. It has the function of program setting. It can be programmed in 7segments, 63 steps, 9 steps

and 1-99 hours and 59 minutes per segment.

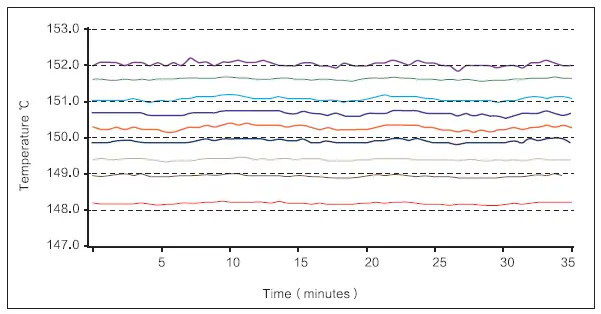

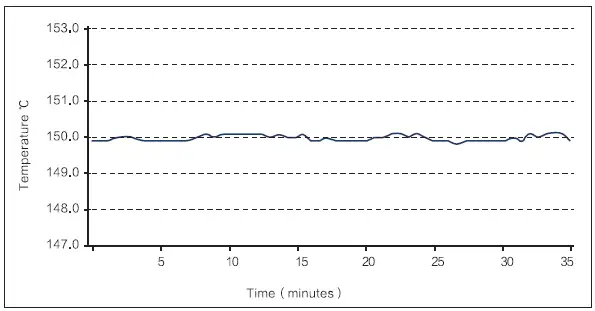

Precise temperature control:

The uniformity of the temperature inside the drying chamber is ≤±2 degree C , so that all samples are heated evenly (Air forced )series.

The uniformity of the temperature inside the drying chamber is ≤±2.5 degree C , so that all samples are heated evenly (Natural Convection) series.

Note: The stability and uniformity are the result under steady state.

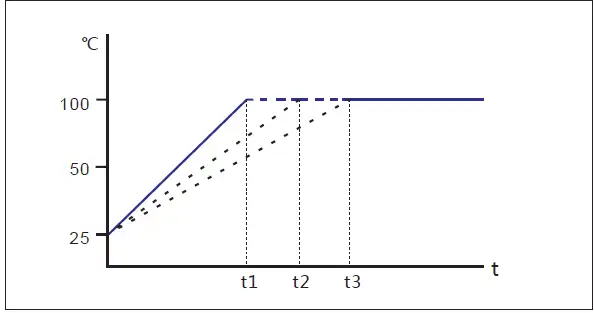

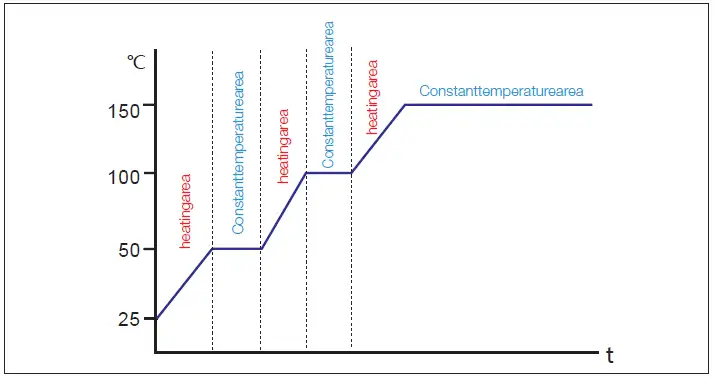

Program control mode, linear temperature rise control.

The temperature fluctuation inside the drying chamber is ±0.3degree C , which ensures the stability of the experiment.

Program control mode, Step heating control.

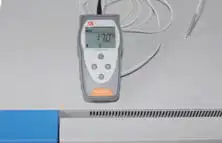

Temperature test hole:

1. External detection sensor can real-time detect the temperature inside the box through the test

hole to ensure the accuracy of the temperature inside the box.

Exhaust regulator:

1. The size of the valve opening can be adjusted arbitrarily according to the actual situation.

2. Air valve adjustment can improve the ventilation efficiency of drying box and prevent excessive heat loss and also improve the uniformity of temperature.

Energy saving design:

1. Comprehensive safety performance design to prevent high energy consumption. New synthetic silicon sealing strip is used to prevent heat loss and prolong the life of heating elements.

2. Compared with traditional equipment, thermal power is reduced by 25%.

Sample temperature detection:

1. Temperature sensors can be selected to monitor the temperature of samples in real time so as to make the temperature more real and reliable.

2. Control system linkage to achieve the purpose of automatic drying. (option)

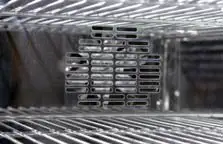

Circulating Fan:

1. Forced convection fan, large impeller fan design, good temperature Uniformity. The fan power is multi-stage adjustable to provide the right airflow for you.

2.The fan power can be adjusted to improve the operation efficiency of the equipment and the service life of the motor. The service life of the motor can be increased by 30%.

Stainless steel inner liner:

1. 304 stainless steel, mirror polishing, strong anti-corruption ability.

2. Large arc angle design, no dead angle, easy cleaning and maintenance.

Professional anti-slid and anti-overturning shelf design:

1. Shelf has anti-inclination function to avoid falling off when shelf is pulled out.

2. Shelf has anti-lock function, the shelf will be locked when it is pulled out half, so as to avoid the loss caused by the direct slide of the shelf.