Class II Biosafety Cabinet BEM1Q2 (BCBS-802)

Class Ii B2 Biological Safety Cabinet- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BEM1Q2 |

| External Size (W*D*H) | 1500*770*2290mm |

| Internal Size (W*D*H) | 1350*600*660mm |

| Tested Opening | Safety Height 200mm(8") |

| Max Opening | 500mm(20") |

| Inflow Velocity | 0.53±0.025m/s |

| Downflow Velocit y | 0.33±0.025m/s |

| ULPA Filter | Two, 99.9995% efficiency at 0.12um, filter life indicator. |

| Front Window | Motorized, two-layer laminated toughened glass = 6mm, anti UV |

| Noise | <67dB |

| UV Lamp | 40W*2UV timer, UV life indicator, emission of 253.7 nanometers for most efficient decontamination. |

| llluminating | LED lamp |

| Lamp | 16W*2 |

| lllumination | ≥1000Lux |

| Consumption | 1300W |

| Waterproof Sockets | Two, total load of two sockets: 500W |

| Display | 7 inch touch screen display: exhaust filter and downflow filter pressure, filter and UV lamp working time,inflow and downflow velocity, filter life, humidity and temperature, system working time etc. |

| Control System | Microprocessor |

| Airflow System | 0% air re-circulation, 100% air exhaust |

| Alarm | Abnormal airflow velocity; Filter replacement; Front window at unsafe height; High filter pressure alarm. |

| Exhaust Duct | 4 meters PVC duct, Diameter:300mm |

| Material | Work Zone: 304 stainless steelMain Body: Cold-rolled steel with anti-bacteria powder coating |

| Work Surface Height | 750mm(Size can be customized according to requirements) |

| Caster | Footmaster caster |

| Power Supply | AC220V±10%, 50/60Hz; 110V±10%, 60Hz (110V/60Hz is not applicable to BSC-180011B2-Pro) |

| Standard Accessory | LED lamp*2, UV lamp*2, base stand, remote control, foot switch, exhaust blower,exhaust duct, drain valve, waterproof sockets*2, pipe strap*2 |

| Optional Accessory | Water and gas tap, Electric height adjustable base stand |

| Gross Weight | 325kg; 56kg |

| Package Main Body | 1650*990*1820mm |

| Package Exhaust Blower (W*D*H) | 930*800*710mm |

Features

LCD Display, 7 inch large touch screen is easy to monitor all the safety parameters at a glance and ergonomically sized control panel improves user interface.

Work zone, made of 304 stainless steel, is surrounded by negative pressure.

Remote Control, All functions can be realized with it making the operation much easier and more convenient.

Footmaster Caster, Universal caster with brake and leveling feet

.

.Foot Switch, Adjust front window height by foot during experiment, to avoid airflow turbulence caused by arm movement.

Front Window, Two-layer laminated toughened glass >5mm, anti UV

UV Lamp, Emission of 253.7 nanometers for most efficient decontamination

Waterproof Socket, 2 waterproof sockets are located in the side wall varp optimum convenience of using small devices inside the cabinet.

1. Larger angle of view,easy to operate and more humanized.

2. Motorized front window.

3. ULPA filter life and UV life indicator.

4. Time reserve function.

5. With memory function in case of power-failure.

6. Self-locking button switch to solve the trouble of losing the key.

7 inch Large touch screen with Intelligent control system: Operators can check detailed status of the cabinet, such as inflow and downflow velocity, work area temperature and humidity, filter pressure, UV working time and filter working time, filter life indicator etc.

8. Audio and visual alarm (filter replacement, window over height, abnormal air flow velocity, etc.

High filter pressure alarm ).

9. Remote control. All functions can be realized with it, making the operation much easier and more convenient.

10. Interlock function: UV lamp and front window; UV lamp and blower, fluorescent lamp; blower and front window

11. Foot switch. Adjust front window height by foot during experiment, to avoid airflow turbulence caused by arm movement.

Operating Manual

Download1. Unpacking, Installation, Debugging

1.1 Unpacking

1.2 Accessories checking

1.3 Installation conditions and using environment

1.4 Installation

1.5 Checking after installation finished

2.User Instructions

2.1 Functions

2.2 Product structure

2.3 Control panel

2.4 Remote Control &Foot switch

2.5 Instructions for Operation

2.6 Daily maintenance

2.7 Methods and procedures for disinfection

2.8 Replacement parts list

2.9 Wiring diagram

3. Trouble shooting and Labels

3.1 Common faults & solution

3.2 Label Description

4. Warranty

5.Exhaust Fan Installation Instructions

1. Unpacking, Installation, Debugging

Please firstly check if packing box is in good condition. If the packing box is damaged, please take photos.

1.1 Unpacking

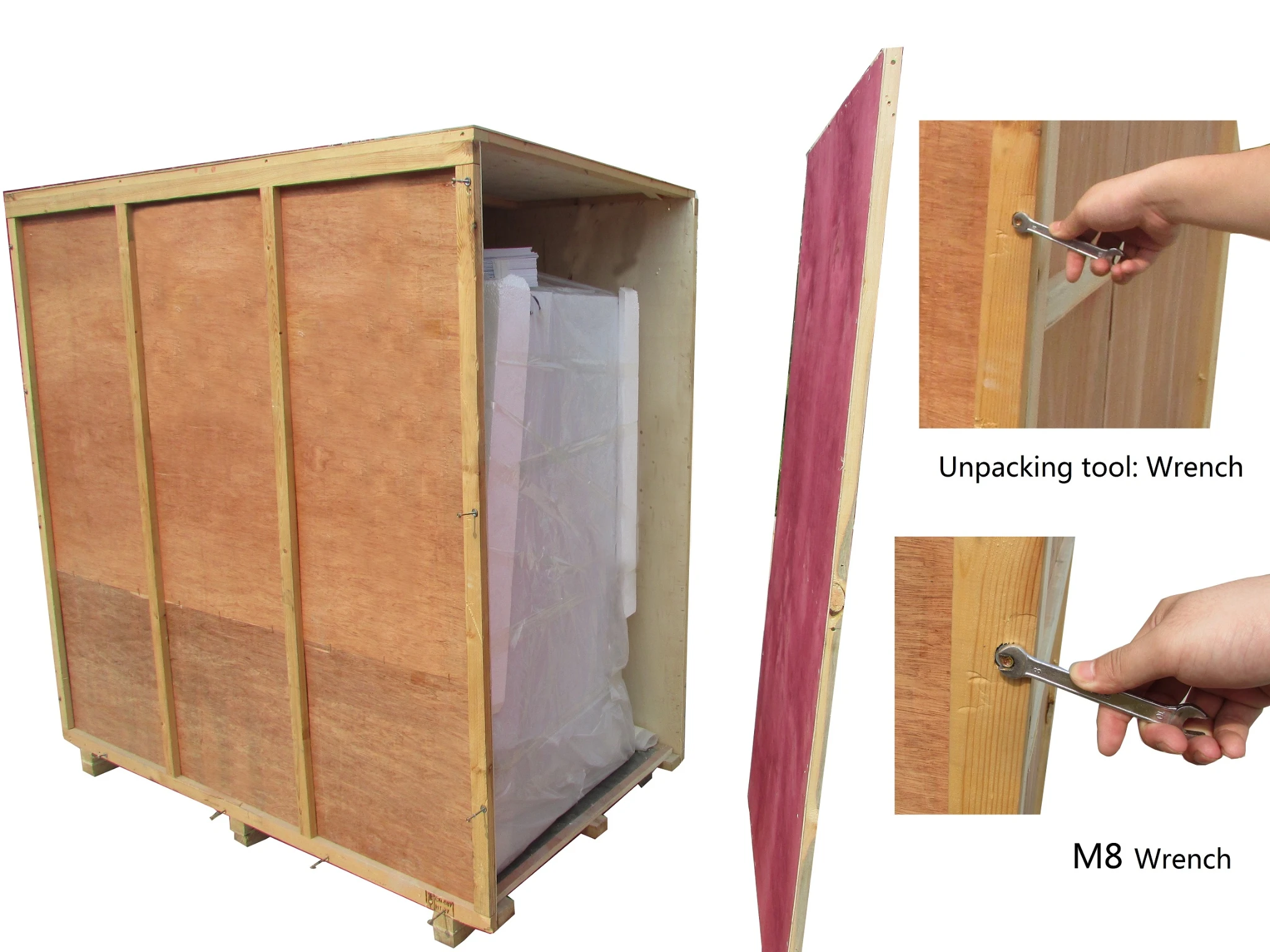

1) Method 1: Use M8 Wrench to unpack

Picture1

2) Method 2: Use M8 Wrench to unpack

Picture 2

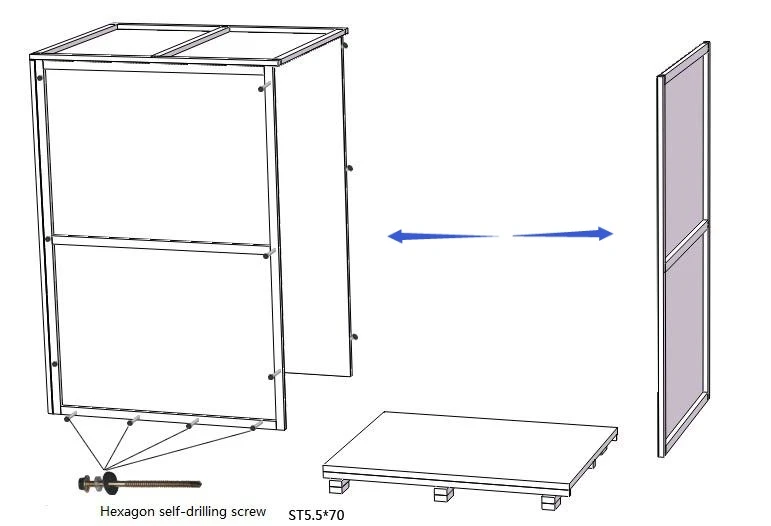

Rapid unpacking diagram (Picture 3). Disassemble the screws shown in the below Picture, then move the wooden pieces to right and left.

Picture 3

1.2 Accessories checking

Refer to the packing list and check the accessories.

Packing list (BCBS-802)

Items | Model | Position | Quantity |

Main Body | Wooden box | 1unit | |

Base Stand | Placed in two carton box | 1set | |

Exhaust blower | Placed in exhaust Wooden box | 1unit | |

Exhaust blower bracket | 1set | ||

Exhaust duct | 1pc | ||

Exhaust duct clip | 2pcs | ||

UV Lamp (T8 40W) | Top or back of main body | 1pc | |

Base Stand | Placed in two carton boxe | 1set | |

Fuse (10A) | Placed in a transparent plastic bag | 2pc | |

Fuse (5A) | 1pc | ||

Remote control (including battery) | 1pc | ||

User manual | 1pc | ||

Test report | 1pc | ||

Quality certification card | 1pc | ||

Foot switch | Placed in the carton accessory box | 1pc | |

Power cord | 1pc | ||

Drain Valve | 1set | ||

Stainless steel hex cylinder head M10x55 bolM10x55t M10x55M10x55 | 3pcs | ||

Stainless steel flat washer10 | 3pcs | ||

Stainless steel spring washer 10 | 3pcs | ||

Hexagon head bolt M8x25 + Flat washer 8 + Spring washer 8 + M8 Screw nut | 4sets | ||

M8*100 Expansion bolt | 6pcs | ||

Transparent glass glue | 1pc | ||

Inner hexagon wrench | 1pc | ||

Big rubber gasket | 1pc | ||

Small rubber gasket | 1pc | ||

Front window tubular motor control rod | 1pc | ||

Buckle stopper (white) | 7pcs | ||

1.3 Installation conditions and using environment

To avoid disturbances to the safety cabinet and its operator, follow the following guidelines, while determining a suitable location for the cabinet:

a. The distance from the plane of the aperture to any circulation space should be at least 1000 mm, so as to preserve a zone undisturbed by anyone other than the operator.

b. Biological safety cabinets should be placed in a position where there should be no opposing wall (or other obstruction likely to affect the airflow) within 2000 mm of the front aperture.

c. Safety cabinets should not be installed in positions where they are likely to be affected by other items or equipment. In particular the distance to the aperture of an opposing safety cabinet, fume cupboard, or the edge of a local exhaust ventilation outlet should not be less than 3000 mm.

d. Any room air supply diffuser should not be within 1500 mm of the front aperture.

e. Doorways should not be within 1500 mm of the aperture or within 1000 mm of the side of the safety cabinet.

f. The position of a safety cabinet should satisfy the spatial requirements (e.g. vision, lighting and convenience of access) of the operator and personnel working nearby. When a cabinet is installed on a bench top, the leading edge should be flush with or slightly overhanging the edge of the bench top.

Working environment:

(1) Only is suitable for indoor.

(2) Ambient temperature: 15°C~35°C.

(3) Relative Humidity: ≤75%.

(4) Atmospheric pressure range: 70 kPa~106 kPa.

(5) Electrical parameters: Consistent with the rated voltage of the biological cafety cabinet (See 2.1.5 technical parameter performance index).

(6) Power supply need to be grounded. (Judging method: testing the fire wire and the zero line of the power supply with multimeter, the fire wire to ground voltage should be grid voltage and the zero line to ground voltage should be 0, otherwise the power supply ground is bad).

(7) Test the voltage stability before using, if the voltage is unstable, should use the voltage regulator, otherwise the control panel and transformer may be easily damaged.

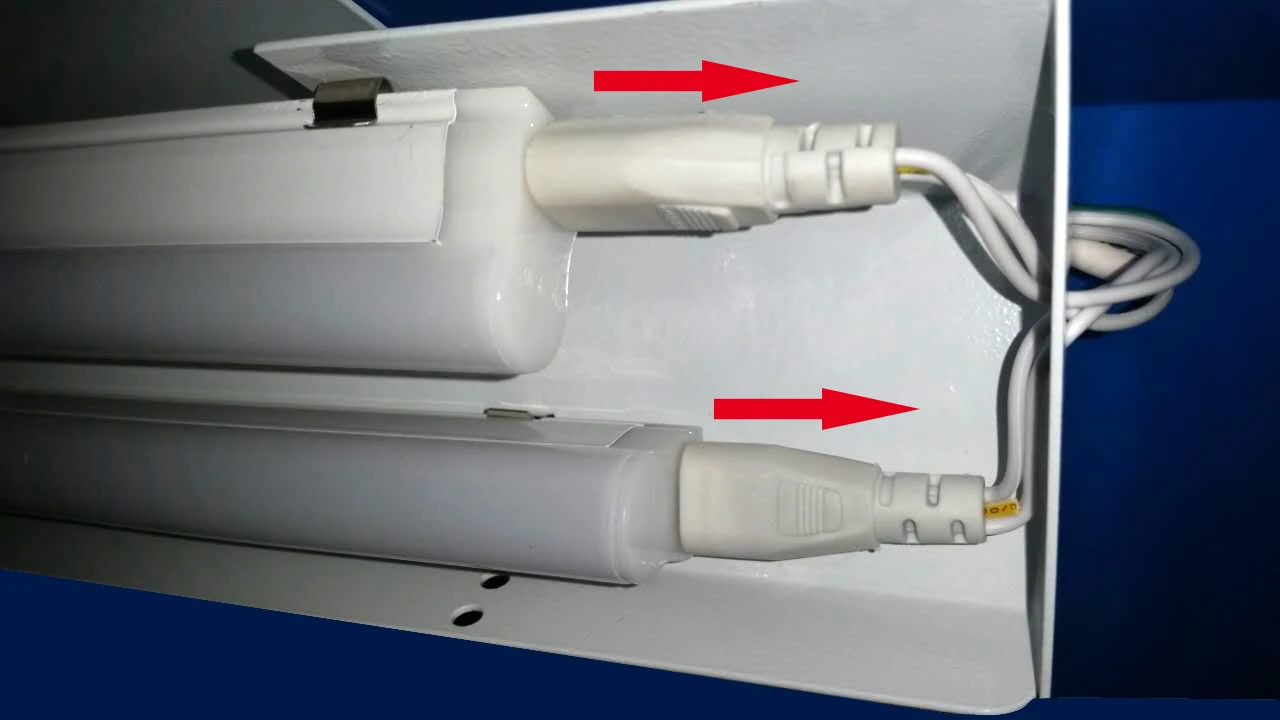

1.4 Installation

a. Remove all the package materials.

b. Inspect the surface of main body to make sure whether there is scratch, deformation or uncorrelated things.

c. Move the whole device to the final installation location.

The base stand will be packed at back of main body, please take it out before installation. DO NOT INVERT, DISASSEMBLE OR TITILE THE CABINET during transportation.

The base stand will be packed at back of main body, please take it out before installation. DO NOT INVERT, DISASSEMBLE OR TITILE THE CABINET during transportation.

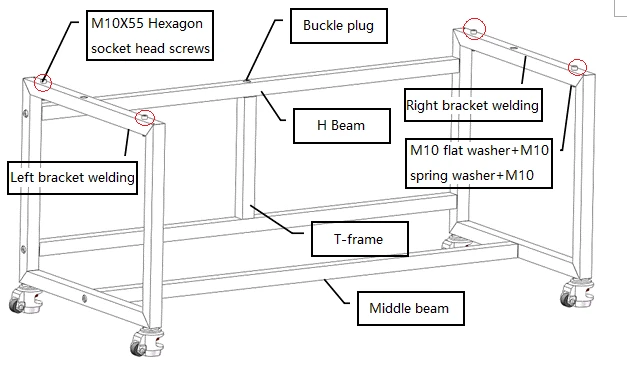

d. The base stand assembly

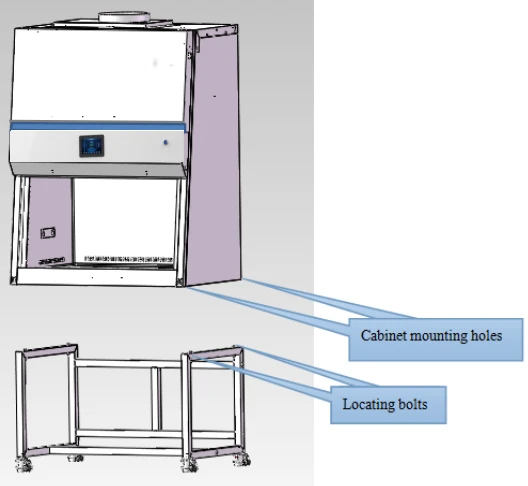

Referring to Picture 4 assemble the base stand.

Picture 4

Remove the M10x55 Hexagon socket head screws, Buckle plug, M10 Stainless steel flat washer, M10 Stainless steel spring washer, M10 Stainless steel cap nuts, referring to Picture 4 assembled base, firmly fastening requirements.

e. Connect base stand and main body

Refer to Picture 5, 6 to connect base stand and main body.

Picture 5

Align the mounting holes on the bottom of the cabinet with the mounting bolts, and the cabinet slowly descending the mounting base

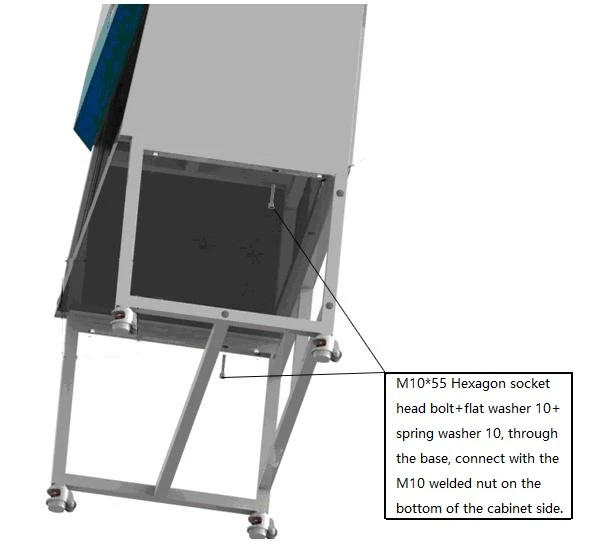

Picture 6

Take out the M10*55 Hexagon socket head screws, Flat washer 10, Spring washer 10 from the accessory box, and fasten tightly according to Picture 6.

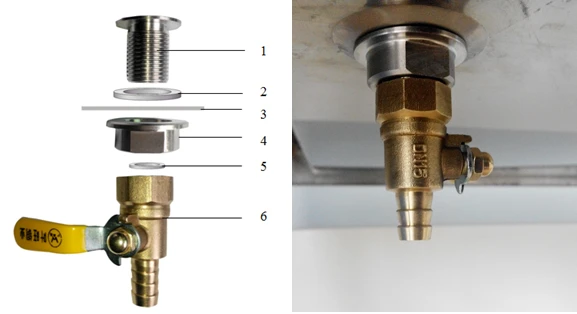

f. Installation of Drain valve

Picture 7

1. Drain valve connect

2. Shim (Inner diameter*outer diameter*thicknessΦ20*Φ28*2mm)

3. Safety cabinet bottom installation holes

4. Ball coupling fastening nut

5. Rubber gasket (Inner diameter*outer diameter*thicknessΦ13*Φ19*2mm)

6. Drain valve

Take out drain valve coupling, shim, Ball nut, Rubber gasket, Drain valve, assembling from up to down as Picture 7 illustrated.

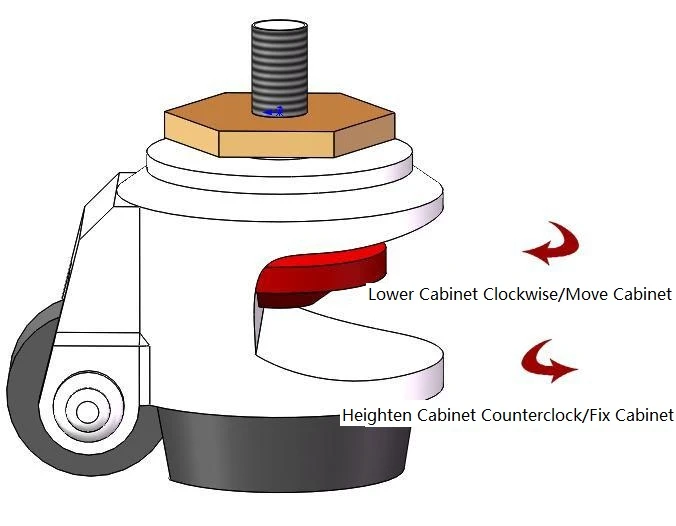

g. Adjustment of Footmaster Caster

Picture 8

Clockwise rotate caster' red part to low down the base feet and the height of the cabinet. Low down all four casters can move the cabinet position. Counterclockwise rotate casters' red part can rise the base leg and height of cabinet. Raise all four casters can at same time can fix the cabinet. Adjust the four Foot -masters makes the cabinet stable.

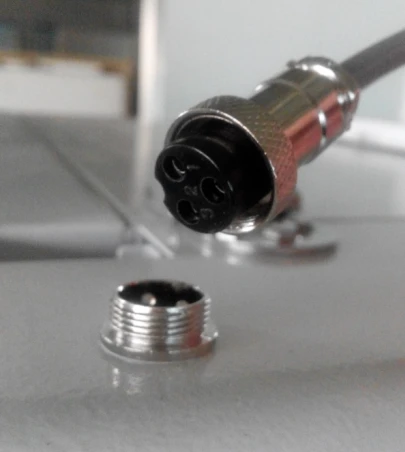

h. Foot Switch

Picture 9

Install Foot Switch as Picture 9. It's socket is at the left top, connect the plug.

i. Installation of Water and Gas Tap(Optional)

Picture 10

1. Fastening Nut

2. Stainless Steel Water and Gas Taps

Take out fastening nuts, water and gas taps, installing as Picture 10.

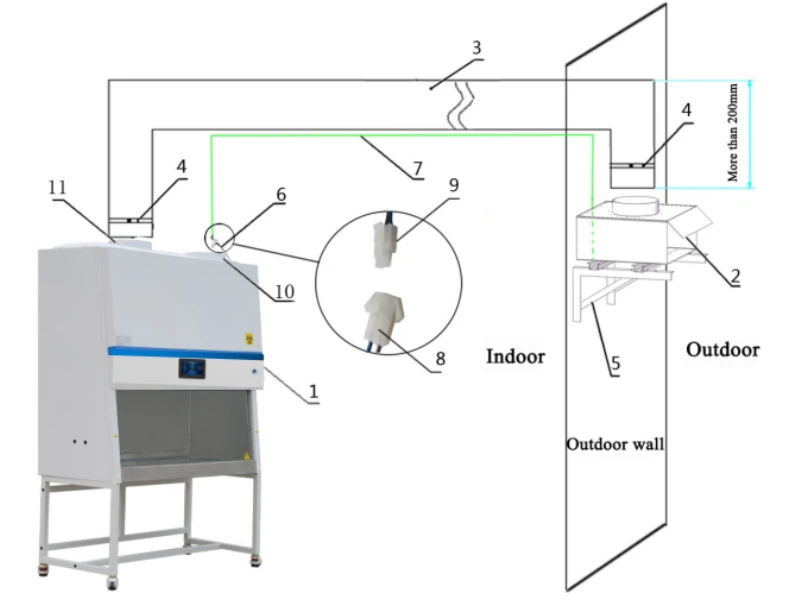

j. Installation of Exhaust blower(For more installation condition please refer to chapter 5)

Picture 11

1. Main Body 2. Exhaust blower 3. Exhaust duct 4. Exhaust duct clip 5. Exhaust blower bracket 6. Butt plug 7. Blower control line 8. Exhaust blower control line interface 9. Exhaust blower control line socket 10. Air feeding 11. Air exhaust

Installation steps:

(1) Place the main body in the original location after it connected with base stand.

(2) Installation the exhaust blower mounting bracket on the outdoor wall (must be solid wall) near the biological safety cabinet (Please carefully check the mounting holes on the exhaust blower when installing the two exhaust blower brackets).using the expansion bolt to fix the exhaust blower bracket on the outdoor wall

(3) Installing the exhaust blower on the exhaust blower mounting bracket by using the hexagon head bolt M8*25,flat washer 8,spring washer 8,M8 screw nut ( Professional installation personnel should operate for ensuring safety ).

(4)Remove the duct, one end set into the exhaust duct clip to connect the main body as shown in picture. Tighten exhaust duct clip.

(5) Remove the other end of the duct out, set into the exhaust duct clip to connect the exhaust blower air inlet as shown in picture11, tighten exhaust duct clip.

(6) Put the exhaust blower control line along the duct into indoor, connect the exhaust blower control line socket with the exhaust blower control line interface.

(1) The duct hole center connected to the exhaust blower must be below the max point center of duct at least 200mm, in order to avoid water or debris along the duct into the main body damaging filters, fans and other internal components.

(2) Please make sure that the main power is off when connecting the exhaust blower controlline.

(3) The customer should have the installation conditions, and reserve exhaust duct hole.

(4) The standard pipe is 4.3 meters the installation is not allowed to appear a lot of bending.

(5) Because this biological safety cabinet is full exhaust type, the equipment installation place need to add air feeding, Air feeding volume for BCBS-802 is 1270m³/h.

1.5 Checking after installation finished

First, make sure the Voltage and frequency to be same as logo showing, and then check the follows items with power on:

Checking Items | Normal situation |

Wind speed display | Inflow 0.53±0.025m/s ,downflow 0.33±0.025m/s |

Pressure display | exhaust filter 120-130Pa, downflow filter 80-110Pa |

Fan running | Normally |

LED lamp | Lamp lights after pressing button |

UV Lamp | Lamp lights after pressing button |

Display screen buttons | All buttons can be used |

Socket | Press the socket key, multimeter testing output supply voltage |

Foot Switch | Red pedal for glass up, black pedal for glass down |

2.User Instructions

2.1 Functions

2.1.1 Product Concept

This products belong to Class II B2 biological safety cabinet.Biological safety cabinet is a kind of negative pressure filtration system for protecting operator, the laboratory environment and work materials, the front opening which air flow inward have protection function for operator, the filtered laminar flow generated by vertical ULPA can protect work materials, what's more, the polluted air flow become pure after processed by ULPA (ULPA) filter. When it's used in microbiology experiment environment filled with volatile or toxic chemical and radionuclide, suitable exhaust hood in function have to be linked.

2.1.2 Application Range

Biological Safety Cabinet is necessary equipment in the laboratory in the search of microbiology, biomedical, DNA recombinant, animal experiment, and biological products, especially in the occasion that operator need to adopt protective measure, such as medical and health, pharmacy, medical research. Our equipment provides a safety working environment which don't have bacterial and dust in the process of bacterial culture.

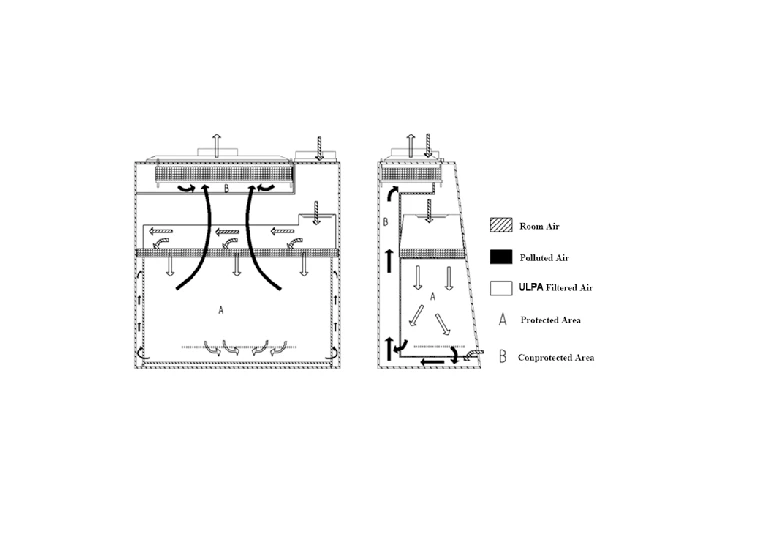

2.1.3 Working theory/Air flow pattern and protected area

Picture 12

2.1.4 Protected objects

Biological safety cabinets (BSCs) are designed to protect the operator, the laboratory environment and work materials from exposure to infectious aerosols and splashes that may be generated when manipulating materials containing infectious agents, such as primary cultures, stocks and diagnostic specimens.

2.1.5 TECHNICAL PARAMETERS

Model Parameters | BCBS-802 |

External Size(W*D*H) | 1500x770x2290 mm |

Working Zone Size(W*D*H) | 1350x600x660 mm |

Power Supply AC | 220V±10% 110V±10% |

Frequency | 50 Hz 60Hz |

Consumption | 1300W |

Total Airflow Volume | 1270m3/h |

UV Lamp Consumption | 40W |

LED lamp Consumption | 16W*2 |

Downflow Velocity | 0.33±0.025m/s |

Inflow Velocity | 0.53±0.025m/s |

ULPA Filter | ≥99.9995%(Diameter: 0.12μm) |

Noise | ≤67dB(A) |

Net Weight | 267KG |

Notes:

(1) Electric consumption power including power which operation area needs to load (Loading no more than 500W)

(2) Our company has right for changing the products, if we need to change and re-design, please forgive us for not notifying you.

2.1.6 Performance Index

1) Biological safety functions

Personnel protection, microbial colony count ≤5CFU.

Sample protection, microbial colony count ≤5CFU.

Cross contamination protection, microbial colony count ≤2CFU.

2) Leak-proof Cabinet

If cabinet pressurized to 500Pa, the pressure should be no less than 450 Pa after 30 min.

3) Integrity of ULPA Filter

Scan and detect the ULPA filter, the leakage rate at any point should not be >0.01%.

Do not Scan and detect the ULPA filter, the leakage rate at any point should not be >0.005%.

4) Vibration amplitude

The net vibration amplitude between frequency 10Hz and 10KHz is no more than 5μm(rms).

5) Illumination

The average illumination is no less than 650 lux, actual illumination is no less that 430 lux.

6) Mechanical performance

Structure design is reasonable, high quality materials are adopted for the cabinet.

It can resist shape global deformation caused by external force.

The working surface will not occur permanent deformation when weight put reaching 23kg.

7) Electrical properties

The voltage increases to 1390V(AC) in 5s and keep for another 5s without breakdown.

Grounding resistance ≤0.1Ω

2.2 Product structure

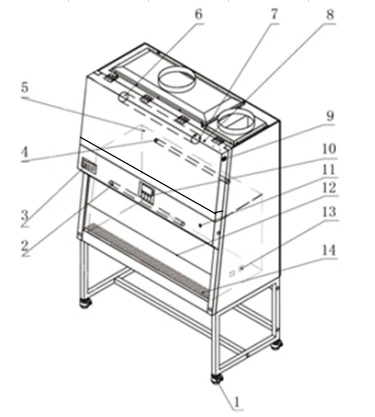

2.2.1 Structural composition

Picture 13

1. Footmaster Caster 8. Blower fuse tube socket

2. LED Lamp 9. Power socket

3. Nameplate 10. Control panel

4. LED Lamp 11. Power supply lock

5. Gas-guide tube 12. Front window

6. Tube motor 13. Water-proof socket

7. General power fuse socket 14. Inflow grid

2.2.2 Structure introduction

1) Driving System of Front Window

Driving system consists of tube motor, front window, hauling sash and position switch.

2) Air Filtration System

Air Filtration System is the most important system of BSC. It consists of blower, supply filter and exhaust filter. The function of Air Filtration System is transferring filtered air to work area, ensure the down flow velocity, and keep Class 100 cleanness of work area.

3) UV Light

UV lamp is inside work area. So UV lamp can well sterilize all space of work area.

4) LED Light

The BSC is equipped with LED lamp. It can make sure average illumination inside work area which meets standard requirements.

5) Air pipe

Air pipe is the ventage of differential pressure sensor.

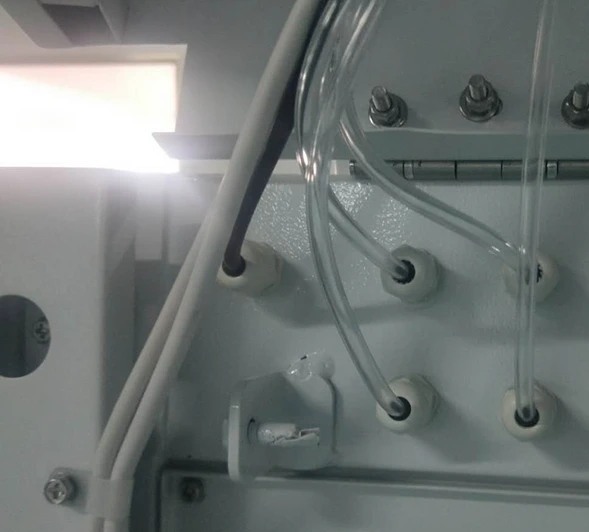

Picture 14

The air pipe should not be blocked and please do not hang anything on the pipes, otherwise it will effect wind speed and pressure.

6) Power lock

When the power cord is connected to main power, switch the key for power lock, then the equipment is powered on.

7) Water proof Socket

Waterproof Sockets are located on the right side of the work area, which can be controlled by SOCKET button.

(1) Please make sure the total load of sockets should be ≤ 500W;

(2) The waterproof socket can only be waterproof when its front cover is lowered, and the socket can not be regarded as a waterproof socket when the front cover is opened.

8) Fuse protector:

The equipment is equipped with main power fuse, waterproof socket fuse and fan fuse. They are located near the power cord's outlet. Fuse label is corresponding to the relevant specifications. Please refer to 3.2.

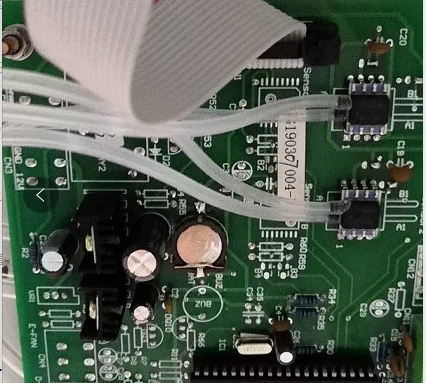

9) Touch screen Display(Liquid Crystal Display)

Picture 15

Large Touch screen display indicates detailed key parameters, it is real-time display to reflect the equipment working condition, such as effective working state of the filter, which is more intuitive. (Please refer to 2.3)

10) Control of Front Window

Front window is motorized. It could be controlled by control panel. Glass door control motor for a dedicated reversible speed motor, the motor has a large starting torque, smooth rotation and so on.

11) Structure

a) Biological Safety Cabinet's both sides and back area are negative pressure air channel. Make a double isolation by air curtain and cabinet between working area and external environment And the working area surrounded by negative pressure to avoid any leakage.

b) Cabinet body is built of 1.2mm cold-rolled steel with anti-powder coating. Strong and steady.

c) Work area is fully made of 304 stainless steel which looks beautiful and with corrosion resistance performance.

d) Base stand is made of cold-rolled steel with anti-powder coating.

e) Soft touch type control panel, easy to handle and beautiful appearance

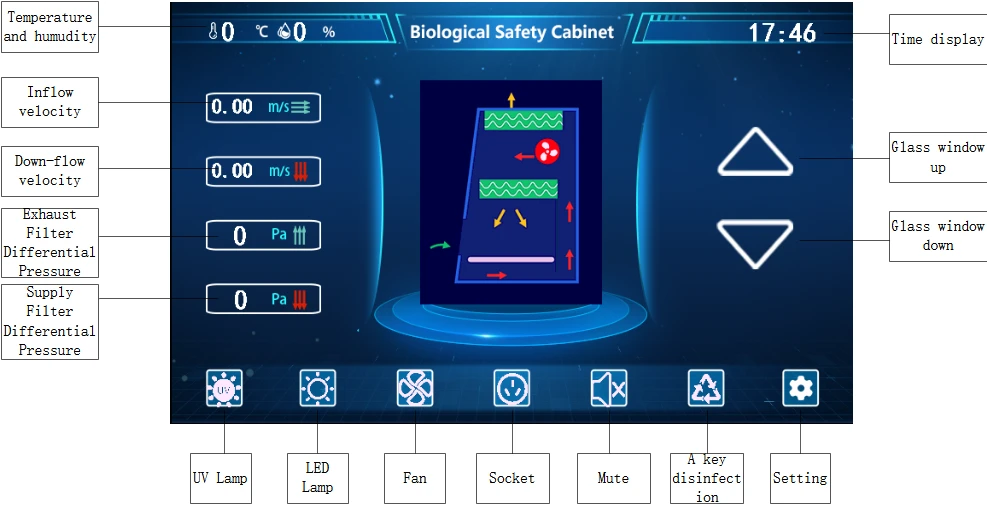

2.3 Control panel

Picture 16

a) LCD Screen

The working status of the equipment and operation can be seen on the LCD screen.

b) Soft touch button.

BSC's main functions could be executed by touch-buttons. User can operate the BSC either by pressing the buttons on control panel or using the remote control. There are totally 8 common button on control panel.

UV lamp: To control UV lamp. (It works only after front window, LED lamp and blower fan are fully closed.)

LED lamp: To control LED lamp

Fan: To control blower working status. (It will not work when front window is fully closed.)

Socket: To control socket power status.

Mute: Press MUTE button to stop voice prompt

A key disinfection:When the glass window is closed, click a key disinfection button, the UV lamp will turn on and automatically turn off after 30 minutes.

Glass window up:Press UP button, glass window will raise.

Glass window down: Press Down button, glass window will fall down.

Clock Adjustment:

Press the time display

Enter year, month, day, hour, minute, second in order

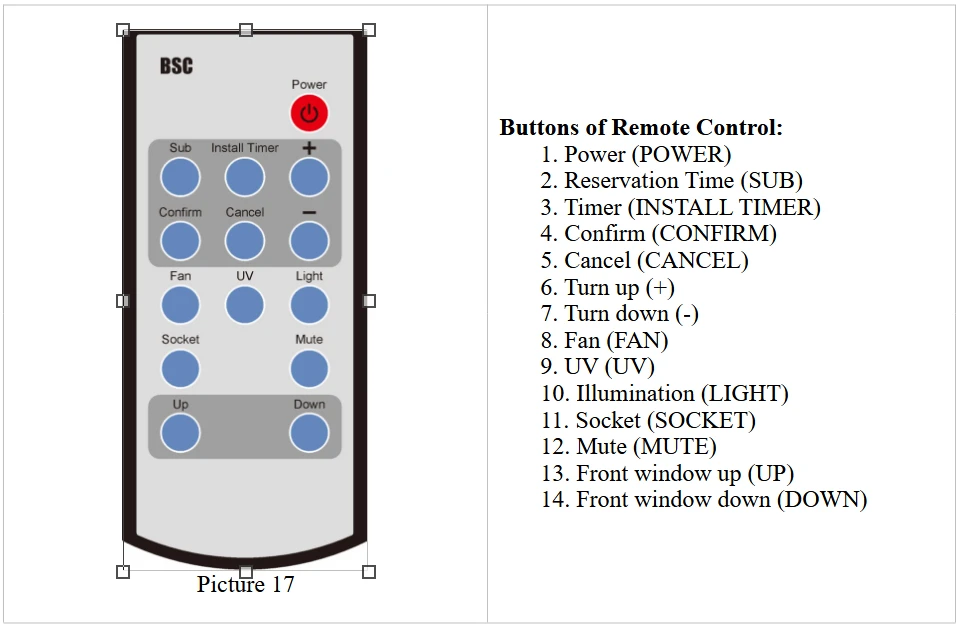

2.4 Remote Control &Foot switch

2.4.1 Remote control

It is inconvenient for the users to operate from a distance. Small & light remote control is flexibly to be used to control all the functions of the cabinet in a distance ≤6m, 30° range. The operator can even carry it with themselves during experiment for convenience.

This remote control adopt specific chip which is featured with good anti-jamming performance,longer control distance and high performance precision

A. Reservation Time (SUB)

a. Connect power, open power lock, and press the reservation timing button (SUB).

b. Adjust the time (minutes) by "+" or "-" button. Press the confirmation button (CONFIRM) to confirm. and then adjust other minutes and hours position data in the same way.

c. After the time is confirmed, the corresponding display lamp lights by selecting the function buttons (such as UV).

d. Press the POWER button again, the reservation function starts. Reserved time starts count down. The corresponding setting function starts when the time counts down to zero.

B. Timer (INSTALL TIMER)

a. Connect power, open power lock, press button (POWER), the corresponding display lamp lights by selecting the function buttons (such as UV).

b. Press button (INSTALL TIMER), adjust the time (minutes) by "+" or "-" button. Press button (CONFIRM) to confirm. and then adjust other minutes and hours position data in the same way.

c. After the time is confirmed, the Timer function starts. When the time counts down to zero, all the functions will be off, the cabinet will be in standby mode.

C. Application of Reservation Time

Biological safety cabinet is equipped with special UV lamp. When turning on or turning off the cabinet, sterilization time of UV lamp should be at least 30 minutes. In order to save the waiting time of turning on or turning off the cabinet, we develop reservation time function. It realizes function of automatic turning on or turning off the cabinet after the sterilization finished. Reservation time setting range is from 0 to 99 hours and 59 minutes. This function helps operators to save time and improve efficiency.

2.4.2 The use of foot switch

Picture 18

Press the left red switch by foot, front window goes up, press the right black switch, front window goes down.

2.5 Instructions for Operation

2.5.1 Normal Operation Notice

(1) Make sure input voltage is correct and stable. The rated load of main power socket should be higher than cabinet consumption. Plug must be well grounded.

(2) In order to avoid air turbulence, the operator should slightly move his arms during experiment. Hands should stay inside the working area at least 1 minute before operating. In order to decrease the times of arms moving into and out of the working area, prepare all the necessary items inside the cabinet before starting experiment.

(3) Moving principles of different samples inside cabinet: When two or more samples need to be moved, be sure that low-polluting samples move to high-polluting samples. Movement of items should also follow the principles of slow-moving.

(4) Samples placed in parallel: Samples should be placed in the cabinet parallel to avoid cross-contamination between samples and blocking back air grille.

(5) In order to avoid samples being sucked into the negative passage or the blower, do not place soft and slight samples (for example: soft tissue) on the surface during experiment.

(6) The weight of items placed in the cabinet should be no more than 23Kg/25x25cm2;

(7) Avoid vibration: avoid using vibration equipment (eg centrifuges, vortex oscillator, etc.) inside the cabinet. Vibration would cause lower cleanliness of operating area and affect operator protection.

(8) No flame: No flame is allowed inside the cabinet. Using of fire will lead to airflow disorder, and filter damage. If sterilization is required during the experiment, infrared sterilizer is highly recommended.

(9) ULPA filter life: With the usage time increasing, dust and bacteria accumulate inside ULPA filter. Filter Resistance is getting bigger, when it reaches the maximum point, there will be audible and visual alarm. Please replace new ULPA filter, otherwise it will affect the safety performance of the equipment. The used filter should be processed as medical waste.

(10)There is a negative passage surrounding the work area, which is sealed strictly in the factory. The operator is not allowed to remove or loose screws of those parts. If necessary, please contact service personal.

(11)Front Grille is used for air intake and drain. Do not block it, otherwise it will affect airflow. Armrest is recommended to solve this problem and reducing the operator's wrist fatigue.

(12)Long-term use of biological safety cabinets will inevitably cause pollution (e.g. ULPA filters, corner cabinets, etc.). In order to sterilize thoroughly every 500 hours, formalin (formaldehyde) fumigation sterilizer is recommended. After sterilization, neutralize formaldehyde gas with ammonium hydrogen carbonate. Make sure no sterilization gas escapes during the whole process.

(13)The maximum storage period is one year. If the period is more than one year, performance test should be done

Serious declaration: we will take no responsibility for risks caused by improper operation and man-made damages!

2.5.2 Operation Process

a. Connect the same power reply, as required of equipment

b. Open the power lock, LCD display lights up and alarm rings at the same time, then the machine enters to standby status. Waiting for the operator to input button to use it.

c. Press POWER button, then the following functions are available: LED lamp. UV lamp, Fan, Mute, Sockets, Front window up and down, Reservation timing

When front window is open or other button is pressed, the UV lamp can not be work.

d. Before doing experiment, please sterilize the cabinet for more than 30 minutes by UV lamp( the front window must be closed)

(1) For safety of eyes and skin, people should leave room during the UV sterilization.

(2)UV lamp intensity should be tested regularly. If there is no test conditions, it should be replaced, recommend once for three month.

e. Please move the front window at 200mm height from the work table, turn on the fan, make sure the experiment should be started after fan working for at least half an hour.

For operating safety, please put testing materials inside the cabinet in advance, and keep the front window at 200mm height from the work table during operation.

For operating safety, please put testing materials inside the cabinet in advance, and keep the front window at 200mm height from the work table during operation.

After finishing the experiment, please move the front window down to the bottom, and make sure to sterilize the cabinet by UV lamp for 30 minutes before turning off the cabinet.

2.6 Daily maintenance

Because the operating time will directly affect the judgment of maintenance needs, we recommend the user keep a detailed record of operating time for reference.

When doing maintenance, please pay attention to cut off the power, so as to avoid electric shock

When doing maintenance, please pay attention to cut off the power, so as to avoid electric shock

2.6.1 Preparations before maintenance

Soap, hot water or warm water, a soft cotton cloth, dry cloth or towel, medical alcohol or other disinfectants, 100 dilution of household bleach, abrasive household cleaners, sterile water

2.6.2 Clean the cabinet surface

1) Clean the operating area surface

Wipe the entire surface with a soft cotton cloth or towel soaked with concentrated liquid soap, then wipe up the soap with another cotton cloth or towel soaked with clean hot or warm water, and then wipe the surface with a dry cotton cloth or towel rapidly.

For the contaminated or dirty work surface or sump., use 70% medical alcohol or other disinfectant to wipe.

Disinfectants used for wiping should not damage 304 stainless steel.

Disinfectants used for wiping should not damage 304 stainless steel.

2) Clean the external surface and front window.

Use soft cotton cloth or towel to wipe the surface with non-abrasive household cleanser.

2.6.3 Overall maintenance period

We suggest comprehensive maintenance period is one year or 1000 working hours.

2.6.4 Maintenance methods

1) Daily or weekly maintenance

a. Disinfect and clean operating area.

b. Clean the external surface and front window around the operating area.

c. Check the various functions of equipment.

d. Record this maintenance result

2)Monthly maintenance

a. Clean the the external surface and front window.

b. Wipe the working table, inner wall surface of operating area (excluding the wind distributing grid of operating area) and the inner surface of glass door with 70﹪ medical alcohol or household bleach diluted 1:100 (i.e, 0.05% sodium hypochlorite). Then wipe again with sterile water in order to eliminate the rest chlorine.

c. Check the various functions of equipment.

d. Record this maintenance result.

3) Annual maintenance

a. Check the two conveyor belts of front window drive unit, and ensure that their tightness is coincident.

b. Check the UV lamp and LED lamps.

c. Apply for testing the overall performance of cabinet on an annual basis to ensure the performance safety. User is responsible for testing costs.

d. Record this maintenance result.

2.6.5 Storage conditions

Safety cabinet should be stored in a relative humidity no more than 75%, the temperature is below 40°C, in the warehouse with good ventilation performance, no acid, no alkali and no other corrosive gases, storage period shall not exceed one year, safety cabinet for more than a year needs to unpacked and checked. Only the tested and qualified safety cabinet can be sold.

2.7 Methods and procedures for disinfection

Details in the After-sale service manual

Disinfection is necessary when any contaminated part of the biological safety cabinet needed for routine maintenance, replacement filters, and performance testing, etc. Before doing certification test and gas sterilization, all internal working surface and the exposed outer surface should be disinfected with a suitable disinfectant. what is more, using Class II biosafety level designated medicament to sterilize the cabinet by gases is required. Class III biosafety level designated medicament is recommended after the use of the cabinet. The cabinet, under the risk of being polluted by the biological factor, should be sterilized before sliding position.

The polluted working surface caused by overflowed and spilled reagents also should be sterilized. Most of the cases that need gas sterilization use depolymerized triformol as the disinfector as noted below, the period parameters and its validity of each model and size of the cabinet are required to be listed before change sterilization method. The relevance of the material has connections with the absorption and degeneration of spare decontaminant, which is the key factor of keeping the cabinet integrated and the sterilization time. There need those alternative sterilization way in some case, such as: slow disease virus. The sterilization method is used against the consult between the end user and certification authority. Pointing out the given area, gas mask, safeguard procedures, corresponding test, medical monitoring, conveying danger and training, record and reserve etc... and follow these steps

Before sterilization, all the hydrogen chloride should be moved away from the cabinet. There will result in carcinogenic substance-BCME when it meet with formaldehyde under the ambient air.

Before sterilization, all the hydrogen chloride should be moved away from the cabinet. There will result in carcinogenic substance-BCME when it meet with formaldehyde under the ambient air.

a. Figure out the total volume by multiplying the height, width and depth.

b. The required weight of the triformol will be worked out through the total volume multiply 11g/m³, figuring out the weight of ammonium bicarbonate or its alternative by chemometry.

c. It must be bubble-tight if there are exhaust pipe with the biological safety cabinet, which can be realized at the end of the pipe or sealing at the control valve if there is valve nearby the cabinet, it need more triformol to compensate the added volume if the length of exhaust pipe is more than 3 meters. If the exhaust recirculation of the cabinet connect with the exhaust system of the construction, interrupting the connection system of the biological safety cabinet with construction and sealing (by using plastic film and plastic strips)

d. Sealing by plastic film as the waste gas is exhausted into the room from biological safety cabinet.

e. In order to urgently eliminate formaldehyde, sterilize and eliminate formaldehyde after neutralizing, putting a tube nearby the biological safety cabinet in advance which is required to connect with chemical smoke hood or other exhaust devices that is suitable for releasing the harmful gas.

f. Put the heater, such as electric-heating frying pan which can be bought from market, formaldehyde generator or neutralizer on the working table. Set up the temperature at 232°C~246°C, the triformol is spraying over the surface of the heater devices equably.

The autoignition temperature is paraformaldehyde at 300°C.

The autoignition temperature is paraformaldehyde at 300°C.

g. The neutralizer with the heating device is placed on the workbench. Neutralizers (Ammonium bicarbonate or equivalent) should be isolated from the air in the cabinet before use. The following two examples illustrate how to achieve air separation.

Eg.1

Ammonium bicarbonate or substitute is uniformly sprayed on the heated surface of the heating device and covered with aluminum foil to prevent the carbonic acid hydrogen ammonia or its substitute in disinfection reaction with formaldehyde. The aluminum foil

should be placed so that ammonia can be released during heating or ready to remove aluminum foil at the beginning of the neutralization phase. Removal of aluminum foil is not allowed when the formaldehyde leakage out of the safety cabinet of.

Eg.2

The safety cabinet with the gloves for a whole plastic film sealing. Ammonium bicarbonate or equivalent substitutes are placed in a container in a safety cabinet. During the neutralization phase, the disinfected personnel into the safety cabinet through the gloves do not break the sealing system. The ammonium bicarbonate or equivalent substitutes are removed from the sealed container and uniformly sprinkled on the heating surface of the heating device, then the heating device is energized, the ammonium bicarbonate or the substitute is heated to release the ammonia.

h. Putting heating plate, water beaker and hygrothermograph on the work table, do not connect the wires to the power supply in the cabinet.

i. Sealing the front operating window with thick plastic film and plastic strips. Seal all the area where possible to leak. Such as wire outlet, the surrounding of front operating window and joint between plastic film and biological safety cabinet.

j. Measure the temperature and humidity inner the cabinet.

k. The humidity is at 60%~85% when temperature is above 21°C, heating the water in the beak up to the expected temperature and humidity.

l. Before depolymerizing the formaldehyde, strictly restrict entry to the area around biological safety cabinet or room in accordance with related regulation and safety measures.

m. Connect the wire of the heater with socket outside the cabinet.

n. 25% formaldehyde is depolymerized open the safety cabinet fan 10s ~ l5s. After the para-formaldehyde is depolymerized by 50%, 75% and 100%, repeating the above steps. If the safety cabinet fan does not work, use auxiliary fans to promote air circulation in the cabinet, or prolong the disinfection time over step.

o. Disconnect the power supply of the heating plate and heater for the use of triformol

p. Keep the biological safety cabinet isolation at least 6 hours, it is better to leave it for a night.

q. Prepare the neutralizer, power off the heating device and the fan of biological safety cabinet until ammonium bicarbonate wiped away, the operation of triformol is also the same, after the decomposition of 20% ammonium bicarbonate, open the fan for 10 s~l 5 s, using assisted fan or electric fan to promote the air circulation inner biological safety cabinet or prolong the neutralization time for at least 6 h if the fan of the biological safety cabinet does not work.

r. Keep the biological safety cabinet isolation at least 1 hour before open the sealing membrane.

s. If exhausting the formaldehyde caused by neutralization via tube, tear out the plastic cover in the exhaust pipe, connect it with tube and seal. The plastic cover in the front of the biological safety cabinet will be suck in and cut one or two openings make the fresh air be into the cabinet if the tube work well, then the formaldehyde is exhausted via tube.

2.8 Replacement parts list

BCBS-802 replacement parts list

Number | Name | Specification |

1 | Fuse | 10A |

2 | Fuse | 5A |

3 | Lamp holder T8 | LG13-01A |

4 | UV Lamp | T8 40W |

5 | LED Lamp | 16W |

6 | UV lamp ballast | 1*TL8-36W |

7 | Upper filter (Exhaust filter) | 1100*420*105 |

8 | Lower filter (Supply filter) | 1380*470*69 |

9 | Supply fan | FH355A |

10 | Exhaust Fan | SC400A2-AG5-00 |

11 | Control panel | control board (strong circuit board, weak circuit board, touch screen) |

12 | Remote control (with battery) | |

13 | Locking press button | LA38-20S/203 |

14 | Glass | 1419*720*6.38 |

15 | Foot switch | Dual pedal (line length 4 meters) |

2.9 Wiring diagram

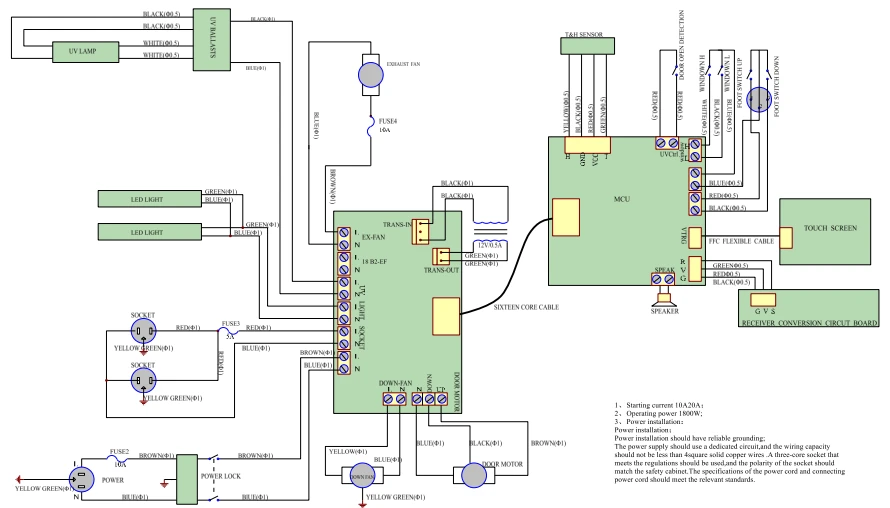

BCBS-802 Wiring diagram

3. Trouble shooting and Labels

3.1 Common faults & solution

3.1.1 Warning and reminder

Digital display of pressure difference, digital velocity display, audible and visual alarm system.

1) Over safety height alarm for front window

There will be audio and visual alarm when front window is lifting over safety height. Same time LCD display will twinkle exclamation mark. Then just adjust the height of the front window.(Front window height setting value is 200mm).

2) ULPA filter pressure difference alarm

There will be audio and visual alarm if pressure of air supply filter or exhaust filter can't meet present value, at the same time LCD display will twinkle exclamation mark. Remind the operator to replace the filter immediately to protect the operator's safety.

3) Velocity fluctuation alarm

There will be audio and visual alarm if the inflow velocity and down flow velocity below 20% of the standard value, namely, inflow velocity below 0.42m/s, down flow velocity below 0.26m/s, at the same time LCD display will twinkle exclamation mark to remind the operator pay attention.

3.1.2 Trouble shooting

Please confirm whether the power is connected or not, whether the power cord is obvious damaged or not, whether the fuse is good or not, and whether the power locks are in the open state or not before the fault diagnosis.

Faults | Check parts | Measures |

LED lamp doesn't work | Circuit | Check circuit |

LED tube | Change it | |

Control panel | Change it | |

UV lamp doesn't work | Front window, LED lamp and blower | Check the front window, LED lamp and the blower is open or not. |

Lamp holder | Tube and lamp holder is connected securely. | |

Circuit | Check circuit | |

UV lamp | Change it | |

Micro Switch | Check if Micro Switch is broken | |

Control panel | Change it | |

Button doesn't work | Control panel | Make sure the power connects well and the fuse is well |

Check if the button is broken | ||

Make sure the connecting wire is connected well | ||

Change control panel | ||

Supply fan doesn't work | Front window | Front window is open or not, blower works only when the front window is open |

Micro Switch | Check if Micro Switch is broken or works fine | |

Blower | If blower is broken, change it | |

Circuit | Check circuit | |

Control panel | Change it | |

Exhaust fan doesn't work | Circuit | Check circuit |

Exhaust fan | If exhaust fan is broken, change it | |

Control panel | Change it | |

No electricity in socket | Socket fuse | Check if socket fuse is broken |

Socket | Check if socket is broken | |

Circuit | Check circuit | |

Control panel | Change it | |

Pressure or air speed displayed incorrectly | Gas circuit | Check whether gas circuit has dropped, is broken, or jammed |

Control panel | Change it | |

Front window doesn't work | Circuit | Check circuit |

Motor of front window | Check front window motor | |

Transmission part | Check transmission connection and lead rail | |

Control panel | change it | |

Foot switch doesn't work | Circuit | Check circuit |

Control panel | Change it | |

Remote control doesn't work | Remote Control | Check if the Remote control is broken or not, and if there's electric in the battery |

Connection cable | Check whether main control panel and display board is connected well. | |

Control panel | Change it | |

No electricity in equipment | Power supply | Check power supply connects well |

Power wire | Check whether power wire has obvious damage | |

Fuse | Check if the fuse is good | |

Power key | Check if power key is open, is broken or not | |

Transformer | Check whether the transformer works normally | |

Control panel | Change it | |

Display doesn't work | Connection winding displacement | Connection winding displacement |

Display screen | Display screen | |

Control panel | Control panel | |

No alarm | Micro switch | Check whether the micro switch is good, and it works normally or not. |

Circuit | Check whether connection circuit of micro switch is good. | |

Control panel | Change it |

NOTES

NOTES

(1) The above electrical parts must be operated by a qualified electrician in safety conditions (cutting off power supply). The other parts are not allowed to remove. otherwise the user should take responsibility by them.

(2) When failures are not occur, and the operator can't solve, please notify our maintenance department immediately. For your safety, please do not maintain equipment by yourself.

(3) The maintenance of this equipment is undertaken by trained and recognized technicians.

(4) If you need to order parts, contact the agent or our technical service department, and please indicate the model and serial number of the cabinet purchased.

3.1.3 Simple accessories replacement

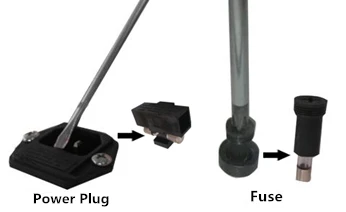

1) Replace the fuse

Socket, fan fuse are located in the top operation panel. When replace them, turn off the power and disconnect plug, use a Phillips screwdriver counterclockwise pressing screwed fuse holder, remove the fuse out and replace a new fuse, and then clockwise pressing screwed fuse holder. Firewire fuse is located in the side of the cabinet operation panel, take out of the fuse holder using a slotted screwdriver and replace with a new fuse, and then press it back.

Picture 19

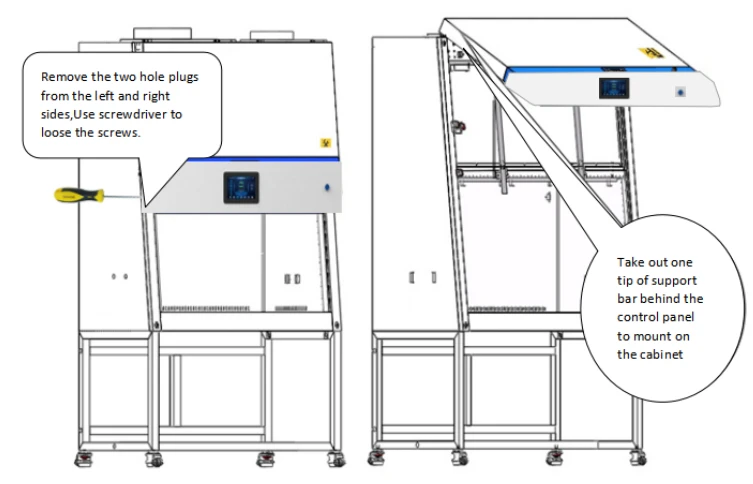

2) Replace LED light

When replacing lights, make sure that the power is off, open the operation panel like shown in Picture, use the control panel support frame (fixed in the inside position of the control panel as shown), then like Picture shown screwing the tube 90°, take the correspondence type of lamp, put it to the lamp holder and screw 90 °to the right position.

Picture 20

Picture 21

3) Replace the UV lamp

UV lamp should be replaced regularly according to the frequency of use, when using UV lamps reach to the time of 600 hours, we recommend to replace the lamp. When replacing, first make sure the power is off, and then screw the bulb 90 ° and take it off , then take the correspondence type of lamp, and put it to the lamp holder and and screw 90 ° in reverse direction. After replacing the UV lamp, it needs to keep pressing the button of UV for about five seconds when the machine stays standby.

Picture 22

3.2 Label Description

1)Biological hazard label

Picture 23

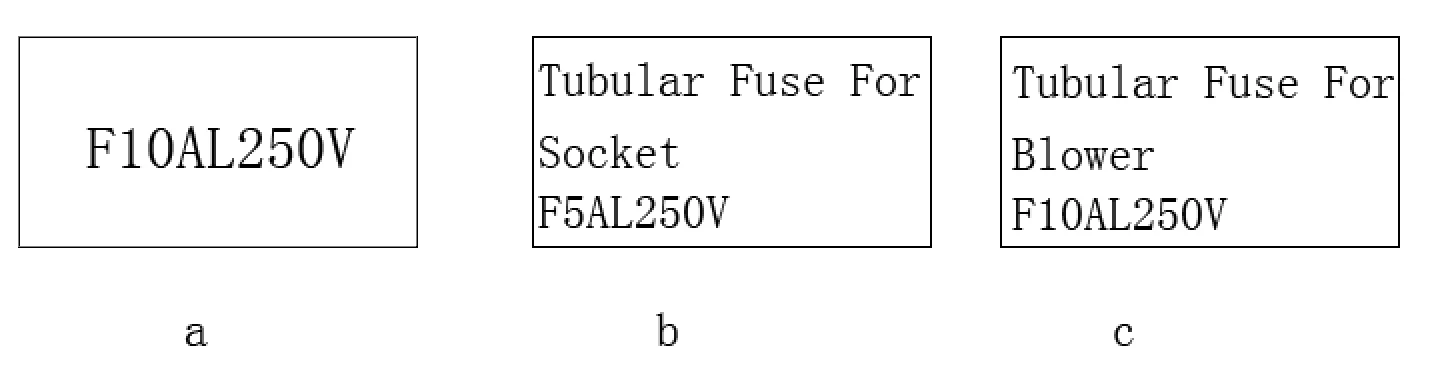

2)Fuse label

Picture 24

Note:

a.10A power fuse label

b. Operating area 5A socket fuse labels

c.10A blower fuse label

3)Ground label

Picture 25

4)Glass door super elevation warning label

Picture 26

5)UV lamp alarm label

Picture 27

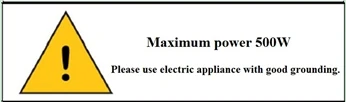

6)Load requirements label

Picture 28

7)Exhaust filter upstream label

Picture 29

8)Downflow filter upstream label

Picture 30

9)Air outlet label

Picture 31

10)Air supply inlet label

Picture 32

4. Warranty

1) Warranty is 1 year from EX-factory date (excluding consumable accessories, UV and LED lamp, fuse).

2) We will take no responsibility for risks caused by improper operation and man-made damages.

3) After the expiration of warranty, our company is also responsible for repairs, but the corresponding maintenance cost should be charged.

4) Life time of biological safety cabinet is 8 years from production date on the label.

5) We can provide equipment drawings and necessary technical data for maintenance companies or personnel trained by our company.

Warranty declaration: One-year Warranty, Life-long Maintenance.

5.Exhaust Fan Installation Instructions

Part A

According to the actual installation situation, choose whether to use the double-tube type external exhaust fan:

1. Single cylinder type external exhaust fan usage:

The external wall of hospitals, laboratories, etc. can be perforated.

At this time, the shell of the external exhaust fan is generally a single-tube type external exhaust fan housing. The specific parameters are as follows:

(1) BCBS-802

Outer fan model: SC400A2-AG5-00

Single cylinder size: 824*695*383 (mm)

Single cylinder type housing accessories

Drawing No. | Name | Quantity |

AAA-25 | outer fan shell welding | 1 |

AAA-26 | Suction port welding | 1 |

AAA-27 | air outlet slanting shutter | 1 |

AAA-49 | fan bracket 2 pieces | 2 |

2. Use of double-tube type external exhaust fan:

①The external walls of hospitals, laboratories, etc. are not allowed to punch holes.

②pipe is too long

③When connecting the exhaust system of the building, it is necessary to place the outer fan casing on the mezzanine.

In such cases, it is generally necessary to use a double-tube type external exhaust fan housing. The specific parameters are as follows:

(1) BCBS-802

Outer fan model: SC400A2-AG5-00

Double cylinder size: 824*695*383 (mm)

Double barrel type housing accessories

Drawing No. | Name | Quantity |

AAA-25 |