Home Water Purification System

Water Purification System

Laboratory Water Purification System

Laboratory Water Purification System

Laboratory Water Purification System BLPS-103

Laboratory Water Purification System BLPS-103

Water Purification System

Water Purification System

Laboratory Water Purification System

Laboratory Water Purification System

Laboratory Water Purification System BLPS-103

Laboratory Water Purification System BLPS-103

Laboratory Water Purification System BLPS-103

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Laboratory water purification system uses double stage reverse osmosis technology. It produces double stage RO water, Deionised, EDI and ultrapure water. These systems have 3 way on-line water quality sensor, multiple alarm with unique design and it has easy-to-replace cartridges pack unit.

- Double stage reverse osmosis technology.

- With tap water inlet, to produce double stage RO water and ultrapure water,quality can reach to18.2 MΩ.cm.

- Built-in 5.8 liters PE tank and 10 liters airtight plastic pressure water tank.

- Built-in 1st stage RO pump,2nd stage RO pump and circulating sanitizing pump.

Specification

Features

Applications

| Feed Water Requirements*: | |

| Water Inlet | Tap water |

| Temperature | 5-45°C |

| Pressure | 1.0-4.0 Kgf/cm² |

| Bacteria | <0.1 cfu/ml |

| DimensionLxWxH | 545x470x610 mm |

| Weight | 20 kg |

| Power Consumption (W) | 240 W |

| Power Supply | AC110-220 V, 50/60 Hz |

| Note | *The quality of output water accords with the quality of inlet water. |

| Ultrapure Water Quality: | |

| Heavy Metal Ion | <0.1 ppb |

| Feed Water Requirements: | |

| Output | 12 L/hrs at 25°C |

| Flow rate (with pressure tank) | >1.5 L/min |

| Resistivity (25°C) | 18.2 MΩ.cm |

| TOC* | 3 ppb |

| Particle (>0.1µm) | <1/ml |

| Conductivity of 2 stage RO water | 1-5µs/cm* |

- Double stage reverse osmosis technology.

- With tap water inlet, to produce double stage RO water and ultrapure water,quality can reach to18.2 MΩ.cm.

- Built-in 5.8 liters PE tank and 10 liters airtight plastic pressure water tank.

- Built-in 1st stage RO pump,2nd stage RO pump and circulating sanitizing pump.

- Unique design and easy-to-replace cartridges pack unit.

- Data storage and RS 232/USB communication port.

- 3 way on-line water quality sensor,multiple alarm.

- Life-span of cartridges' display and alarm.

- System circulation function,system sterilization procedure.

- The graphic display clearly indicates all system's parameters. From water quality to knowing when it is time to change the purification pack,you'll see at a glance what is need.

- For ease-of-use,the main purification technologies are contained in an innovative all-in-one pack that mean you can change it in just a couple of minutes.

- The system requires no special installation,connect the system to your tap water supply it's ready to use.

Laboratory, Manufacturing, Reefkeeping, Aquarium, Laboratory, Research

Operating Manual for BLPS-103

1. Preface

2. Specification

3. Working Environments

4. Installation

4.1 Preparation for installation

4.2 Tube and adapter’s connection

4.3 Installation steps

5. Usage Guide

5.1 Starting Up

5.2 Getting Corresponding Pure Water

5.3 Standby

5.4 Shutdown

5.5 Releasing Internal Air Of Terminal Filter

5.6 The Usage to Keep High Quality Pure Water

6. Microcomputer Controller

6.1 Panel

6.2 The Specific operation method

6.3 Specification at the beginning of working process

6.4 Specification of the main interface

6.5 Specification of main menu icon

6.6 Specification of alarm

7. Warranty & Repair Regulation

1. Preface

Dear customer, in the beginning, we sincerely thanks for your choosing our water purification system. This water purification system has incorporated new cutting-edge technology. It is installed and used easily, and can provide you with RO water and ultrapure water for science research. So, it will benefit your work. For the water purification system’s maximum efficiency, it is suggested that the user manual should be read before installation. Any question in the installation process, please contact our technology engineers or dealers.2. Specification

| Model | BLPS-103 | BLPS-203 | |

| Output -2nd stage RO water* | 12 or 24 liters/hour | ||

| Output -ultrapure water | Up to 2 liters/minute (when tank is full) | ||

| Ultrapure water quality | |||

| Resistivity(25℃) | 18.2MΩ.cm | ||

| TOC* | <3ppb | ||

| Bacteria | <0.1cfu/ml | ||

| Particle(>0.1μm) | <1cfu/ml | ||

| Endotoxin | N/A | ||

| RNases | N/A | ||

| DNases | N/A | ||

| RO water quality | |||

| Conductivity - 1st stage RO water | Feed water conductivity×5%* | ||

| Conductivity - 2nd stage RO water | 1-5μs/cm* | ||

| Feed water requirements | Tap water, temperature:5-45℃,pressure:1.0-4.0Kgf/cm2 | ||

| Dimension and weight | Length×Width×Height:545×470×610mm / Weight: 25Kg | ||

| Electrical requirements | AC220V, 50Hz | ||

| Power | 240W | ||

| Standard configuration | Main body (Including 1 set of cartridge)+built-in 12 liters pressure tank | ||

| Purification System | |||

| Sequence number | Specification | Quantity/set | |

| LV.1 | D-pp pretreatment cartridge | 1 | |

| LV.2 | D-ak Kinetic degradation fluxion cartridge | 1 | |

| LV.3 | D-ac2 active carbon block cartridge | 1 | |

| LV.4 | 12 series- 150GPD RO membrane | 1 | |

| 24 series- 200GPD RO membrane | 1 | ||

| LV.5 | 12 series- 50GPD RO membrane | 1 | |

| 24 series- 100GPD RO membrane | 1 | ||

| LV.6 | D-uvcart (254&185) nm wavelength uv cartridge | 1 | |

| LV.7 | D-pocart ultrapure polishing resin cartridge | 1 | |

| LV.8 | D-tefit (0.45+0.1) μm terminal filter | 1 | |

REMARKS:

*The value will be influenced by temperature and feed water’s quality.

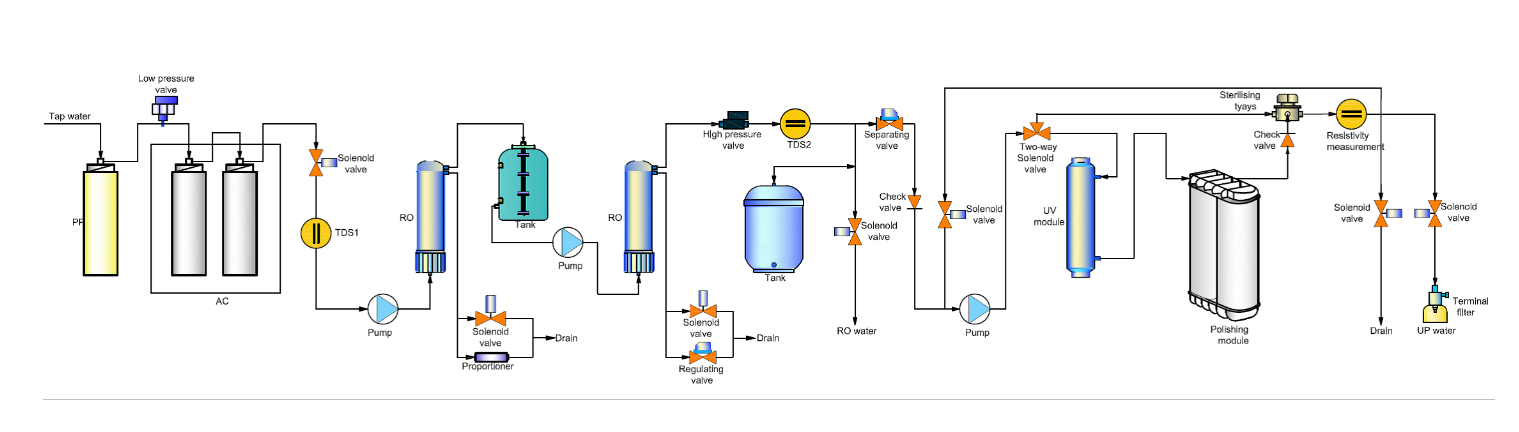

Water Flow Chart

3. Working Environments

- Inlet wate r: Tap water (TDS<200ppm will be suggested).If inlet water TDS>200ppm, pretreatment is recommended. Water with higher TDS will affect the quality of outlet water and life of purification cartridge.

- Work temperature: 5-45℃

- Pressure: 1.0-4.0Kgf/cm 2

- Power: AC220V,50Hz,240W

- Clean, dry working environments would be suggested

4. Installation

4.1 Preparation for installation

The purification system should be installed horizontally and near to tap.4.2 Tube and adapter’s connection

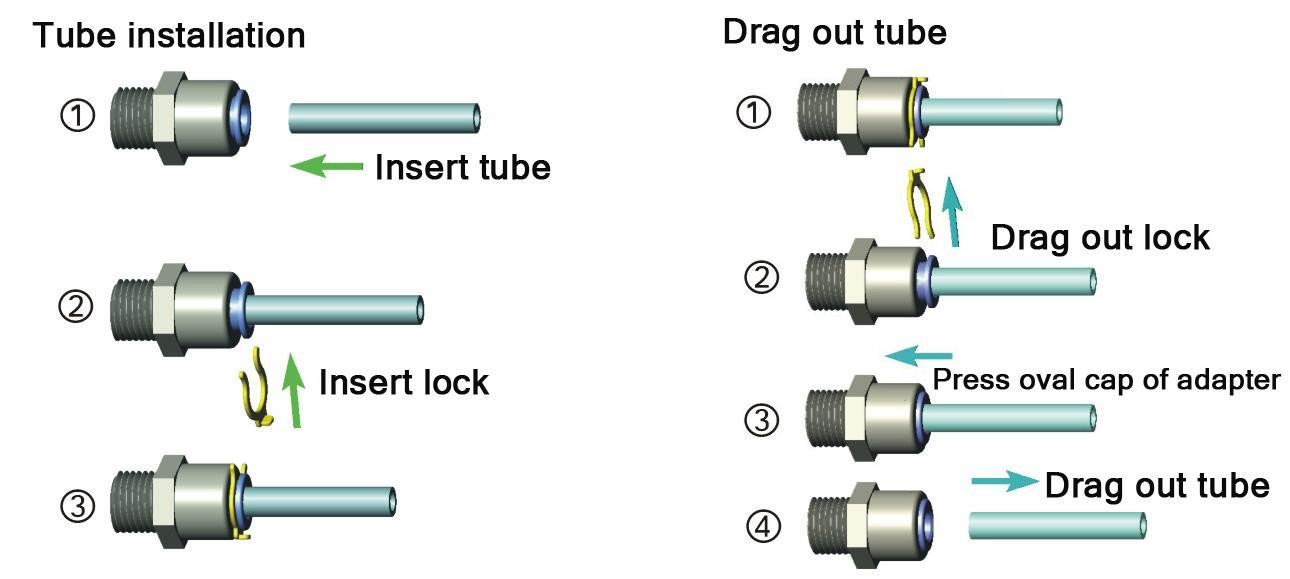

The adapter of the machine is high quality easy-put adapter. And material of tube is high quality’s PE.Tube installation and drag diagram

The tube should be cut with special tube cutter for rounded cut section. And rounded cut section should be guaranteed as much as possible with other cut tools.

Connect the tube-press the oval cap of the interface strongly, then insert the tube to the bottom of adapter.

Take off the tube-press the oval cap of the interface strongly, then drag out the tube. Do not drag when the tube can’t be dragged out any more.

The fore-end of the tube, which has been inserted to adapter, should be cut, when it will be used again.

Sufficient PTFE thread seal tape should be used in all the threaded joints for water leakage inhibitor or preventing.

4.3 Installation steps

1. Open the packing-case, take out main body, accessory box, water tank (optional) .

2. Take out adapters and tube from accessory box, and read the Instruction Manual carefully .

3. External interface are on the back of machine, and it is labeled with different color’s label. Moreover, its adapters are inserted with different color’s stop plug .

ATTENTION -

ATTENTION -Stop plug should be pulled out before the following steps

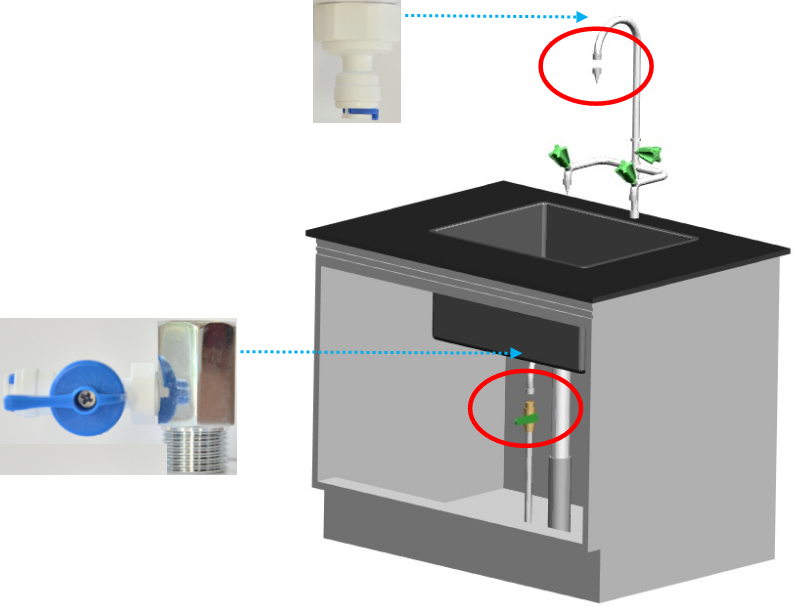

4. Connect To Tap Water

There are two ways to connect to the tap.

1.

1 and 2 is the place where the interface of machine’s inlet water should be connected.

1 st way-with tap water adapter 1(1/2″internal thread to 3/8″fast-plug) to connect to tap water.

1. Step: connect tap water adapter 1 to water source

Close the valve of the gooseneck. Dismantle the faucet of gooseneck. Screw tap water adapter 1 into the external thread of gooseneck.

2. Step: connect tap water adapter 1 to interface of machine’s inlet water

Use 3/8” PE tube with a suitable length. Insert one side into the interface of tap water adapter 1, and insert the other into the interface with blue label marked “To inlet water” at the back of machine.

2 nd way-with tap water adapter 2(tee joint and 3/8″ball valve) to connect to tap water.

1. Step: connect tap water adapter 2 to water source

Close the chief valve of tap water. Dismantle the tap.

Screw the 3/8’’ ball valve with external thread into the side thread with internal thread of tee joint.

Screw the tap into the internal thread at one end of the tee joint, and at last, screw the other end with external thread of the tee joint(with 3/8’’ ball valve and the tap at this time) into the internal thread of the tube, where the tap has been connected.

ATTENTION:

ATTENTION:Sufficient PTFE thread seal tape should be used in all the threaded joints for water leakage inhibitor or preventing

Step: connect tap water adapter 2(3/8″ball valve) to interface of machine’s inlet water

Use 3/8” PE tube with a suitable length. Insert one side into the interface of 3/8″ball valve, and insert the other into the interface with blue label marked “To inlet water” at the back of machine.

ATTENTION

ATTENTIONExtra pretreatment filters (optional) should be connected between the water source and main body.

Connect To RO Wastewater

Use 1/4” PE tube with a suitable length. Insert one side into the interface with black label marked “To drain” at the back of machine, and the other side is directed to drain. DO NOT JAM

- Thus the installation is OK.

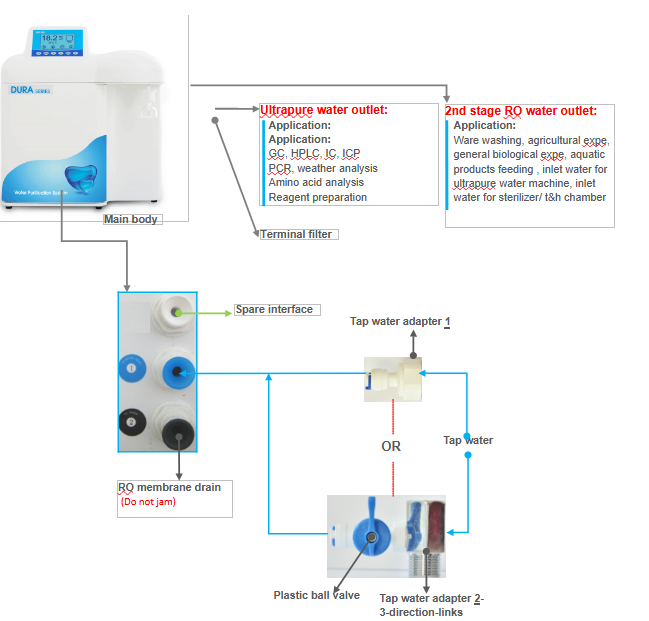

2. Installation Guide Chart

5. Usage Guide

All data have been set in the factory.The machine will operate smoothly without any data-setting and debugging.

All work state will display on the LCD. If there is abnormal state, the system will alarm automatically. If data modification is necessary, specific step is in “Microcomputer Controller”.

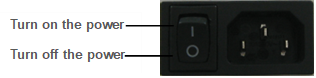

The power switch is on the side of the shell. Specific picture is as follows

5.1 Starting Up

Turn on the tap water valve, insert the power line into the power source and turn on the power switch, then the system begins to produce pure water.5.2 Getting Corresponding Pure Water

Press “ ” or “

” or “  ” buttons, which are on the panel, to get corresponding 2nd stage RO water or ultrapure water(higher quality water than RO water).

” buttons, which are on the panel, to get corresponding 2nd stage RO water or ultrapure water(higher quality water than RO water).5.3 Standby

When 2nd stage RO water and ultrapure water is not for use, the system will be in standby state. The system still produces 2nd stage RO water to store in the interior water tank. Until tank is full, the system will automatically stop. The system will begin to produce pure water again when any pure water is used.5.4 Shutdown

Turn off the tap water valve and turn off the power switch. Then it is ok. ATTENTION

ATTENTIONMake sure that the source water and power source is not connected, when the system is not in the use state for long time (for example, off duty).

5.5 Releasing Internal Air Of Terminal Filter

Unscrew the rounded bolt, which is on the side of terminal filter, open the valve of ultrapure water. When ultrapure water goes out, internal air of terminal filter will be released. Until terminal filter is nearly full of pure water, then tighten rounded bolt. ATTENTION:

ATTENTION:If the internal air of t erminal filter is not released,pure water can not go through the terminal filter for air’s resistance, then the system will stop working for high pressure.

5.6 The Usage to Keep High Quality Pure Water

1. The pure water is easily polluted by surrounding environment. So getting fresh pure water is suggested.

2. Keep water tank from sunlight for microbe’s reproducing.

3. When get high pure water, initial high pure water is suggested to drain to get steady pure water.

4. Avoid air bubble when get pure water to reduce air pollution.

ATTENTION

ATTENTIONThe microbe’s reproducing will reduce the life of cartridge, when the machine does not work for long time. So the machine’s work every 7-10days is necessary.

6. Microcomputer Controller

6.1 Panel

There are 6 buttons on the panel (as shown below).

-

| Control the solenoid valve of 2nd stage reverse osmosis water |

| Control the solenoid valve of ultrapure water |

| Main menu, modify all the function and data of the system. |

| Shift the cursor to corresponding position |

| Adjust the data of chosen position(0-9 circle), or turn on/off different function |

| Confirm the adjusted data and execute corresponding function. |

6.2 The Specific operation method

1. Choose the menu item, which will be researched or modified.

Press “MENU” button to move the cursor to the menu item. The chosen item will be allochroic state. Then press “OK” button to enter corresponding item.

Modify the parameters of menu item or turn on/off the function of menu item.

Press “MENU” button to choose item, shift button“

” to choose the digit, figure button“

” to choose the digit, figure button“  ” to modify the digital of digit or the turn on/off the function of menu item when modification is ok, press “OK” button to confirm.

” to modify the digital of digit or the turn on/off the function of menu item when modification is ok, press “OK” button to confirm.3. Return to upper menu or main interface

Press “MENU” button, and move the cursor to return icon

, then press “OK” button.

, then press “OK” button.6.3 Specification at the beginning of working process

When system is power on, the boot screen (Picture1) will appear for about 5

seconds .

The system will detect the status of feed water after 5 seconds. No feed water or

low pressure of feed water, the system will warn (Picture 2).If the status of feed

water is normal, system will implement the following.

Check TDS and panic value of feed water. Check whether the current TDS of

feed water exceeds the previously panic value. If so, system will warn (Picture 3)

and will not ignore the alarm, until the feed water’s quality is normal or pressing

“OK” button. Then system

switches to the status of flushing RO membrane. If not, sytem will switch to the

status of flushing.

Flushing RO membrane for about 20seconds (Picture 4).At the same time system will detect the status of feed water, No feed water or low pressure of feed water, the system will warn again(Picture 2). When the status of feed water is normal, system will flush the RO membrane again.

After finishing of flushing RO membrane, system will switch to status of producing pure water (Picture 5). At the same time system will detect the status of feed water, No feed water or low pressure of feed water, the system will warn again (Picture 2). When the status of feed water is normal, system will continue to produce pure water.

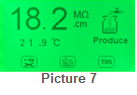

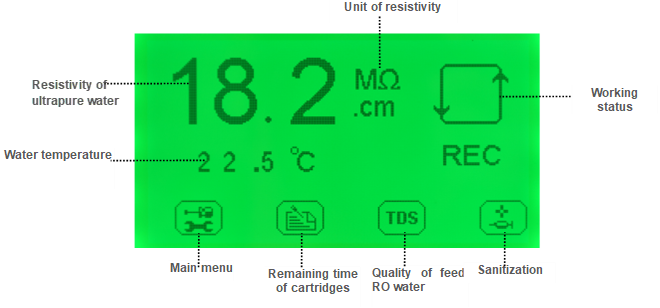

When tank is full, the system will warn (Picture 6).And after a few seconds of full tank alarm, system will switch to main interface (Picture 7).

I f tank is not full, and system is producing pure water (Picture 5), system also can switch to main interface (Picture 7) through pressing “OK” button.

On the status of main interface, system still produces pure water until tank is full, and specific operation can be implemented.

ATTENTION:

Specific operation can be implemented only on the main interface. If system is on the interface of pure water produce (Picture 2) or FULL (Picture 6), please just press “OK” button to switch to main interface.

Specific operation can be implemented only on the main interface. If system is on the interface of pure water produce (Picture 2) or FULL (Picture 6), please just press “OK” button to switch to main interface.6.4 Specification of the main interface

1.

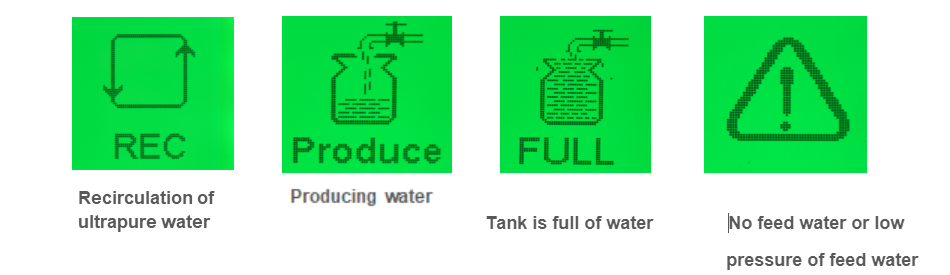

At the top-right corner of the main interface, system will show 4 kinds of working status-REC, Produce, FULL, No water. It respectively means: Recirculation of ultrapure water, Producing RO water, tank is full of water, no feed water or low pressure of feed water.

Definite icons are as follows:

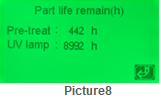

2 .Specification of cartridges’ remaining time icon

Under the main interface, press “MENU” button, move the cursor to icon then press “OK” button to switch to interface of cartridges’ remaining time (Picture 8).

then press “OK” button to switch to interface of cartridges’ remaining time (Picture 8).

Specification of the interface “Pre-treat: 442h”: It means that the PP spun fiber filter’s remaining time is 442 hours (Initial value is 450 hours);

“UV lamp: 8992h”: It means that the UV lamp’s remaining time is 8892 hours (Initial value is 9000 hours ).

REMARKS

REMARKSUV lamp is optional. If there is no UV cartridge in the system, “UV lamp: 8992h” will not show.

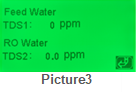

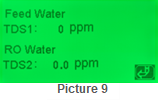

3. Specification of feed water and RO water’s quality icon

Under the main interface, press “MENU” button, move the cursor to icon ,

then press “OK” button to switch to interface of feed water and RO water’s quality (Picture 9).

- Specification of the interface

- Feed water”: It represents the source water or tap water

- TDS1: 0ppm”: It means that the value of feed water’s TDS is 0, the unit is ppm (mg/l)

- RO water”: It represents reverse osmosis water

- TDS2: 0.0ppm - It means that the value of RO water’s TDS is 0.0, the unit is ppm (mg/l).

4.

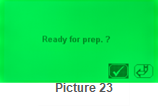

Under the main interface, press “MENU” button, move the cursor to icon , then press “OK” button to switch to interface of sanitization(Picture 23).(Under the main interface, interface of sanitization also can be switched to, through pressing “OK” button 3 times continuously)

, then press “OK” button to switch to interface of sanitization(Picture 23).(Under the main interface, interface of sanitization also can be switched to, through pressing “OK” button 3 times continuously)

At this time, machine would stop working, and prepares for sanitization.

Method of sanitization

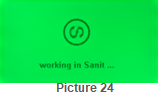

At first, open top cap of disinfection box, then put 1 piece of disinfecting tablet inside, tighten the cap again. Lastly press MENU button, move the cursor to icon , press “OK” button to start sanitization procedure (Picture 24).

Sanitization process will persist for 3-4 hours. During this time, the solenoid valve of pure water outlet will be closed and all the buttons in panel will not be operated.

ATTENTION:

ATTENTION:Shutting off the power and restart are prohibited in sanitization process. Otherwise disinfecting tablet water will enter into pure water cartridge, the service life of cartridge will reduce greatly.

6.5 Specification of main menu icon

Under the main interface, press “MENU” button, move the cursor to icon

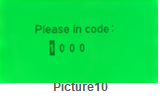

, t hen press “OK” button to switch to interface of password entry ( Picture 10)

, t hen press “OK” button to switch to interface of password entry ( Picture 10)

The initial code is “1000”.

Inputting initial code“1000” through shift button and figure button, then press “OK” button to confirm

If code is wrong, system will warn and return to main interface.

If code is right, system will switch to interface of main menu (Picture 11).

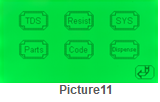

Under the main menu, press “MENU” button, move the cursor to corresponding icon, then press “OK” button to switch to the corresponding menu item.

6.6 Specification of main menu

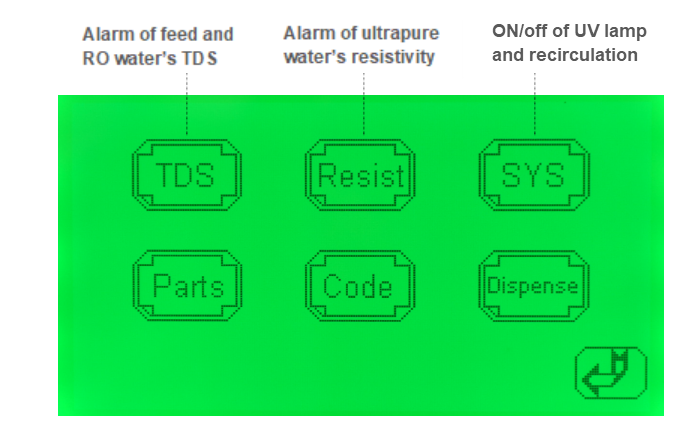

Specification of icon- alarm of feed and RO water’s TDS

Under the main menu, press “MENU” button, move the cursor to icon

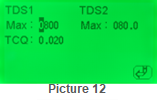

, then press “OK” button to switch to interface of feed and RO water quality’s standard-exceeding alarm setting (Picture 12).

, then press “OK” button to switch to interface of feed and RO water quality’s standard-exceeding alarm setting (Picture 12).

Specification of the interface

TDS1 - It represents TDS of source water or tap water.

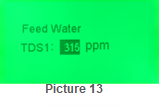

Max: 0800 - It means when the TDS value of TDS1 exceeds 800 ppm(initial setting value), the system will warn and display the interface of feed water quality’s standard-exceeding alarm (Picture 13).

TDS2”: It represents TDS of RO water.

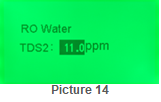

Max: 080.0 It means when the TDS value of TDS2 exceeds 80 ppm(initial setting value), the system will warn and display the interface of RO water quality’s standard-exceeding alarm (Picture 14)

TCQ: 0.020 - It represents that temperature compensation coefficient is 0.020 (initial setting value, any modification is prohibited).

REMARKS:

REMARKS:TDS1-feed water quality’s standard-exceeding alarm is effective only when the machine just start.

The value of TDS1 which system display is definite feed water’s quality (Picture 13).

When the TDS value of actual feed water’s quality < Max(setting value),system will cancel the alarm.

- The purpose of feed and RO water quality’s standard-exceeding alarm

- The purpose of TDS1’s alarm(feed water quality’s standard-exceeding alarm):Remind that the feed water’s quality is bad, and the extra pretreatment is necessary to protect the cartridges of main body.

- The purpose of TDS2’s alarm(RO water quality’s standard-exceeding alarm):Remind that RO water’s quality is bad, and RO membrane should be replaced to protect the post cartridges.

- Setting method of feed and RO water quality’s standard-exceeding value

- The TDS value of feed and RO water quality’s standard-exceeding alarm can be modified according to the local feed water’s quality in the course of machine.

- General principles of alarm value setting

TDS1’s Max value: Slightly larger than the actual measured value;

- TDS2’s Max value: ≤TDS1’s Max value×10%. Because the desali nizat ion ratio of new RO membrane is above 95%.( TDS2’s Max value ≤TDS1’s Max value×5%)

- The method of alarm value setting

- In the interface of feed and RO water quality’s standard-exceeding alarm setting (Picture 12),press MENU button, move the cursor to corresponding item, reset it through shift and figure button, at last press OK button to confirm.

Specification of icon- alarm of ultrapure water’s resistivity

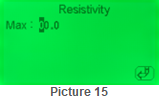

- Under the main menu, press MENU button, move the cursor to icon , then press “OK” button to switch to interface of ultrapure water resistivity’s standard-exceeding alarm setting (Picture 15).

- Specification of the interface

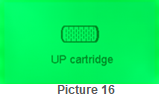

Max: 00.0 - When the actual resistivity of ultrapure water is less than 0 MΩ.cm (initial setting value), the machine will warn to remind ultrapure water resistivity’s standard-exceeding. And system will display interface of ultrapure polishing resin cartridge replacement’s reminding (Picture 16).

REMARKS: When the resistivity of ultrapure water exceeds the standard setting value, the system will warn 1 times every 10 seconds. During this time, the solenoid valve of pure water outlet will be closed. If opening solenoid is necessary, the value of ultrapure water resistivity’s standard-exceeding must be reset.

REMARKS: When the resistivity of ultrapure water exceeds the standard setting value, the system will warn 1 times every 10 seconds. During this time, the solenoid valve of pure water outlet will be closed. If opening solenoid is necessary, the value of ultrapure water resistivity’s standard-exceeding must be reset.- The purpose of ultrapure water resistivity’s standard-exceeding alarm

Remind that the actual value of resistivity is lower than the setting value. Maybe the quality of ultrapure is not suitable for the experiment. Replacing the ultrapure polishing resin cartridge is necessary.

- Setting method of ultrapure water resistivity’s standard-exceeding value

The resistivity’s value of ultrapure water resistivity’s standard-exceeding can be reset according to actual requirement for ultrapure water.

- General principles of alarm value setting

According to actual requirement for ultrapure water

The method of alarm value setting

In the interface of ultrapure water resistivity’s standard-exceeding alarm setting (Picture 15), press MENU button, move the cursor to corresponding item, reset it through shift and figure button, at last press “OK” button to confirm.

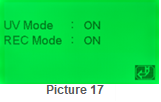

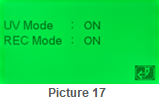

Specification of icon- ON/OFF of UV lamp and recirculation

Under the main menu, press “MENU” button, move the cursor to icon

, then press “OK” button to switch to interface of UV lamp and recirculation ON/OFF (Picture 17).

, then press “OK” button to switch to interface of UV lamp and recirculation ON/OFF (Picture 17).

Specification of the interface

UV Mode: ON”: It means that the monitoring function of UV lamp is turned on. (OFF means turning off)

REC Mode: ON - It means that the recirculation function is turned on. (OFF means turning off)

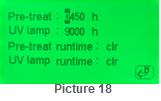

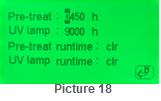

Specification of icon- setting and clear of cartridges’ life

Under the main menu, press “MENU” button, move the cursor to icon , then press “OK” button to switch to interface of setting and clear of cartridges’ life (Picture 18).

Recirculation function is optional. Some models have no this function, if so, REC Mode’s initial setting is OFF. Otherwise, it is ON.

- The purpose of UV lamp and recirculation ON/OFF

UV lamp alarm: means that life of UV lamp is over, replacement of UV lamp is necessary.

Recirculation ON/OFF: system can restrain bacteria’s increase and keep high quality’s ultrapure water

- Setting method of UV lamp and recirculation ON/OFF:

In the interface of UV lamp and recirculation ON/OFF (Picture 17), press MENU button, move the cursor to corresponding item, reset it through shift and figure button, at last press OK button to confirm.

Specification of icon- setting and clear of cartridges’ life

Under the main menu, press “MENU” button, move the cursor to icon

, then press “OK” button to switch to interface of setting and clear of cartridges’ life (Picture 18).

, then press “OK” button to switch to interface of setting and clear of cartridges’ life (Picture 18).

Specification of the interface

Pre-treat - 0450h - It means that the PP spun fiber filter’s initial setting time is 450 hours. When its runtime exceeds 450 hours, the system will warn and display the interface of pretreatment cartridge replacement’s reminding (Picture 19).

“UV lamp: 9000h”: It means that the UV lamp’s initial setting time is 9000 hours. When its runtime exceeds 9000 hours, the system will warn and display the interface of UV lamp replacement’s reminding (Picture 20).

Pre-treat runtime: clr”: clear the runtime of pretreatment cartridges to zero, system will reset timer

UV lamp runtime: clr”: clear the runtime of UV lamp to zero, system will reset timer.

REMARKS:

REMARKS:- The above 2 operation are implemented generally on the condition of replacing cartridges.

- UV lamp is optional. If there is no this part, “UV lamp: 9000h”, “UV lamp runtime: clr” and “Picture 20” will not display.

- The basis for pretreatment cartridge’s life-450 hours is the runtime of system-5 hours every day,30 days every month,3 months.

- The basis for UV lamp’s life-9000 hours is the runtime of system-24 hours every day with Uninterruptible power supply. If the lamp is turned on and off frequently, its life will reduce strikingly.

Setting method of setting and clear of cartridges’ life

- The principle of setting of cartridges’ life: according to the actual replacement term.

Method of setting cartridges’ life: In the interface (Picture 18), press “MENU” button, move the cursor

to corresponding item, reset it through shift and figure button, at last press “OK” button to confirm.

Method of clear of cartridges’ life: In the interface (Picture 18), press “MENU” button, move the cursor to “clr” item, then press “OK” button to confirm.

ATTENTION:

ATTENTION:- Clearing cartridges’ life must be implemented once replacing new cartridge is ok.

Specification of icon- code setting

Under the main menu, press “MENU” button, move the cursor to icon

, then press “OK” button to switch to interface of code setting (Picture 21).

, then press “OK” button to switch to interface of code setting (Picture 21).

- Specification of the interface

0000 - It means that the password is “0000

(ATTENTION: Initial setting password is “1000” )

(ATTENTION: Initial setting password is “1000” )- Method of code setting

For enhancing management of the machine ,If needed, password can be reset to protect system’s parameter from modification.

- Specific method: In the interface (Picture 21), move the cursor to corresponding item, through shift button to choosing the digit and figure button to modifying the digital of digit, at last press “OK” button to confirm. From now on, the initial setting password “1000” is invalid.

ATTENTION:

ATTENTION:- Once new code setting is ok, please make sure to input new password in interface of password entry (Picture 10).

- If new password is forgotten, please no hesitate to contact with our company.

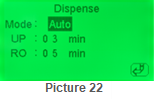

Specification of icon- Mode of getting water

Under the main menu, press “MENU” button, move the cursor to icon , then press “OK” button to switch to interface of getting water’s mode (Picture 22).

- Specification of the interface:

- Mode: Manual - It means that the current mode of getting water is manual.

Specification of manual mode:

Under this mode, press the dispense button first times, then the solenoid valve of pure water is opened. Press the dispense button again, then the valve is closed. )

- Mode: Auto - It means that the current mode of getting water is automatically.

Specification of auto mode

Under this mode, press the dispense button, then the solenoid valve of pure water is opened. And the valve will be automatically closed after the setting time.

ATTENTION: Initial setting mode of getting water is Manual.

ATTENTION: Initial setting mode of getting water is Manual.UP 03min - It means that the getting ultrapure water’s time of auto mode is 3 minutes.

RO - 05min - It means that the getting RO water’s time of auto mode is 5 minutes.

REMARKS:

Time setting is effective only under auto mode;

Time frame: 1 minute to 99 minutes.

- Setting method of getting water’s mode:

In the interface (Picture 22), press “MENU” button, move the cursor to corresponding item, through shift button to choosing the digit and figure button to modifying the digital of digit, at last press “OK” button to confirm.

6.6 Specification of alarm

1- Alarm of no feed water or low pressure of feed water- System continuously monitors the pressure of feed water. If no feed water or low pressure of feed water, system will warn (Picture 2).

- The alarm of starting up and flushing RO membrane:

- Display warning picture 2, accompanied by buzzer alarm. System will continue to flush RO membrane until the pressure is ok.

- The alarm in the process of producing pure water:

- Display warning picture 2, accompanied by buzzer alarm. System will continue to produce pure water until the pressure is ok.

- The alarm in other work status:

- Display warning picture 2, accompanied by buzzer alarm. Warning time will sustain 3 seconds. System will work again after 3 seconds. System will monitor the pressure again every 1minutes.

2- Alarm of cartridges’ life

Including - pretreatment cartridge replacement’s reminding (picture 19), UV lamp replacement’s reminding (picture 20), ultrapure polishing resin cartridge replacement’s reminding (picture 16).

- Alarm of pretreatment cartridge replacement’s reminding (picture 19), and UV lamp replacement’s

reminding (picture 20).

- When the runtime is above the initial setting value of cartridges’ life, system will warn, and display warning picture 2, accompanied by buzzer alarm. Warning time will sustain 3 seconds, and system will monitor the pressure again every 1 hour. It means that system will warn 1 times every hour until the initial setting value is modified or the runtime is cleared to zero.

- Alarm of ultrapure polishing resin cartridge replacement’s reminding (picture 16).

When system’s real time resistivity is less than the initial setting value, system will warn, and display warning picture 16, accompanied by buzzer alarm. Warning will occur every 10 seconds. The solenoid valve of pure water’s outlet will not be opened when system is warning. If opening is necessary, please modify the initial setting value of resistivity’s alarm.

Water Quality Test

The system has 3 monitor sensors of water quality measuring.

- The first, TDS1, monitors feed water’s quality (tap water, inlet water).

Measure unit: TDS(total dissolved solid, ppm)

- The second, TDS2, monitors 2 nd stage reverse osmosis water’s quality(2 nd stage RO water).

Measure unit: TDS(total dissolved solid, ppm)

- The third, Resist, monitors ultrapure water’s quality (Ultrapure water).

Measure unit: Resistivity (MΩ.cm)

REMARKS -

- Under normal conditions, new RO membrane’s desalination rate is above 95%. It means that TDS of RO water should be less than TDS of inlet tap water×5%.

- If TDS of RO water > TDS of inlet tap water×10%, it means that RO membrane’s desalination can’t meet the minimum requirements. RO membrane should be replaced at once.

- Conversion relations between TDS and conductivity rate(µs/cm):

If TDS<50ppm, conductivity rate (µs/cm) ≈TDS×2

If TDS>200ppm, conductivity rate (µs/cm) ≈TDS×(1.5~1.7).

- Consumables

| Item No. | Specification | Quantity/set | Suggested replacement term |

| D-PP | Pretreatment cartridge | 1 | About 2-6 months |

| D-AK | Kinetic degradation fluxion cartridge | 1 | About 12 months |

| D-AC2 | Active carbon block cartridge | 1 | About 4-6 months |

| D-RO-200 | Reverse osmosis membrane | 1 | About 12-24months |

| D-RO-150 | Reverse osmosis membrane | 1 | About 12-24months |

| D-RO-100 | Reverse osmosis membrane | 1 | About 12-24months |

| D-RO-50 | Reverse osmosis membrane | 1 | About 12-24months |

| D-Uvlamp | D-uvlamp (254&185) nm wavelength uv lamp | 1 | About 9000 hours |

| D-Pocart | Ultrapure polishing resin cartridge | 1 | About 4500 liters pure water |

| D-Tefit | (0.45+0.1) μm terminal filter | 1 | - |

REMARKS

- Worse inlet feed water quality or big dosage will reduce cartridge life.

- Normal Trouble Diagnosis

| Normal trouble | Cause | Diagnosis |

| No power | -No plug in -Power adapter broken | -Check the power connecting -Replace new adapter |

| No pure water goes out or a little amount of pure water | -Valve of pure water outlet broken -Pump broken -Cartridges or filters’ life ends | -Replace new valve -Replace new pump -Replace new cartridges or filters |

| Cartridges’ life warns | -Cartridges’ life ends | -Replace new cartridges |

| Water leakage | -Adapter or something broken | -Check, insert and drag out again, replace |

| Water quality deteriorate | -Cartridges or filters’ life ends -Water quality sensor broken | -Replace new cartridges or filters -Replace new water quality sensor |

- All other matters not mentioned herein, please contact us directly.

7. Warranty & Repair Regulation

The products enjoy repair service since the day of purchase. In one year from the purchasing day, we are obliged to replace components for customers free of charge, due to non-human-behavior factors, except for1. All the consumables;

2. Damage caused by maloperation or use in abnormal situations;

3. Disassembly any part of the machine or human-behavior damage;

4. Not repaired by our serviceman.

- Specification can be changed without any prior notice for development.

3.1

3