Freeze Dryer BFFT-105-A

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Compact, stainless steel unit with casters for easy movement, Floor type freeze dryer provides unmatched process accuracy and reliability in performance. It optimizes your space requirements and reduces energy consumption.

- Condenser, operation panel, shelves and trays are made of stainless steel

- Drying chamber is equipped with organic glass for safety and visibility

- Low noise compressor with long shelf life and high efficiency

- Features vacuum freeze drying technology

Specification

Features

Applications Optional Accessories

| Type | T-Floor type |

| Condenser Temperature | < -50°C |

| Water Holding Capacity | 3-4 /24h |

| Vacuum Degree | < 10 Pa |

| No of Sealed Valves | 24 pieces for 24 ampoules |

| Overall Dimension (mm) | 560x460x(710+430) |

| Weight | 80/110 kg |

| Power | 1070 W |

| Power Supply | 220V, 50Hz |

- Condenser, operation panel, shelves and trays are made of stainless steel

- Drying chamber is equipped with organic glass for safety and visibility

- Low noise compressor with long shelf life and high efficiency

- Features vacuum freeze drying technology

- Drying curves are displayed on LCD screen

- Condenser has pre-freezing function

- CFC free environment friendly refrigeration with low maintenance

- Features nitrogen valve and eutectic test device (optional)

Perishable Substances, Waste Products, Laboratory, Research, Proteins, Organic Tissues, Waste Products, Plant Material, Polymers, Pharmaceuticals, Nutraceuticals, Plant material

| Accessory Code | Name | Description | Trays | Temperature |

| 1900606006 | Nitrogen inflation valve | |||

| 1900606007 | Exhaust filter/ Oil mist filter for pump | |||

| 1900606008 | Air inlet filter for pump | |||

| 1900606009 | Anti oil return valve for pump | |||

| 1900606010 | Electricity heating defrosting | |||

| 1900606011 | Electric heating shelf | |||

| 1900606012 | Trays | Trays : dia. 180mm/ dia.200mm | Diameter 180mm/200mm | |

| 1900606013 | RS232 and software | Check and keep freeze drying data on computer; control freeze dryer through PC | ||

| 1900606014 | -80°C Condenser | Minimum condenser temperature as -80°C | Min. condenser temperature as -80°C |

Operating Manual for BFFT-105-A

1. Summary

2. Characteristics and technical parameters

3. Conditions in use

4. Installation and preparations for freeze-drying

5. Operation of pre-freezing and drying process

6. Turn off machine operation

7. Control system operation

8. Notices

9. Common breakdown and elimination

1. Summary

The vacuum freeze–drying technology, which is also called sublimation drying, is a technical method that freezes the samples in advance, and then sublimates its moisture in the vacuum state. Goods are easier for long-term preservation after freeze-drying processing. They can be restored to the original state and maintain their chemical and biological characteristics after being watered. So the freeze-drying technology is widely used in medicine, food, chemistry industry and biological products etc.2. Characteristics and technical parameters

1. Main characteristics(1) SECOP compressor, the refrigeration process is rapid and the condenser temperature is low.

(2) LCD touch screen control system, simple operation and good function.

(3) The control system automatically stores data, and data can be viewed in form of curves. Whole freeze-drying process is clear.

(4) The vacuum pump is connected with host by international standard KF quick joint.

2. Technical parameter

(1) Minimum condenser temperature: -55℃(no-load)

(2) Final vacuum: <10Pa ( no-load)

3. Conditions in use

1. Ambient temperature in normal working condition: 10℃-30℃.Relative humidity: ≤70%.

Power supply: 220V±10%, 50/60Hz, single phase

The working environment should be no conductive dust, explosive and corrosive gases and strong electromagnetic interference.

2.Transport and storage conditions

environment temperature: -40℃~50℃.

Relative humidity: ≤93%.

The storage conditions should be well-ventilated, no corrosive gases.

4. Installation and preparations for freeze-drying

1. Structure of freeze dryer and name of partition

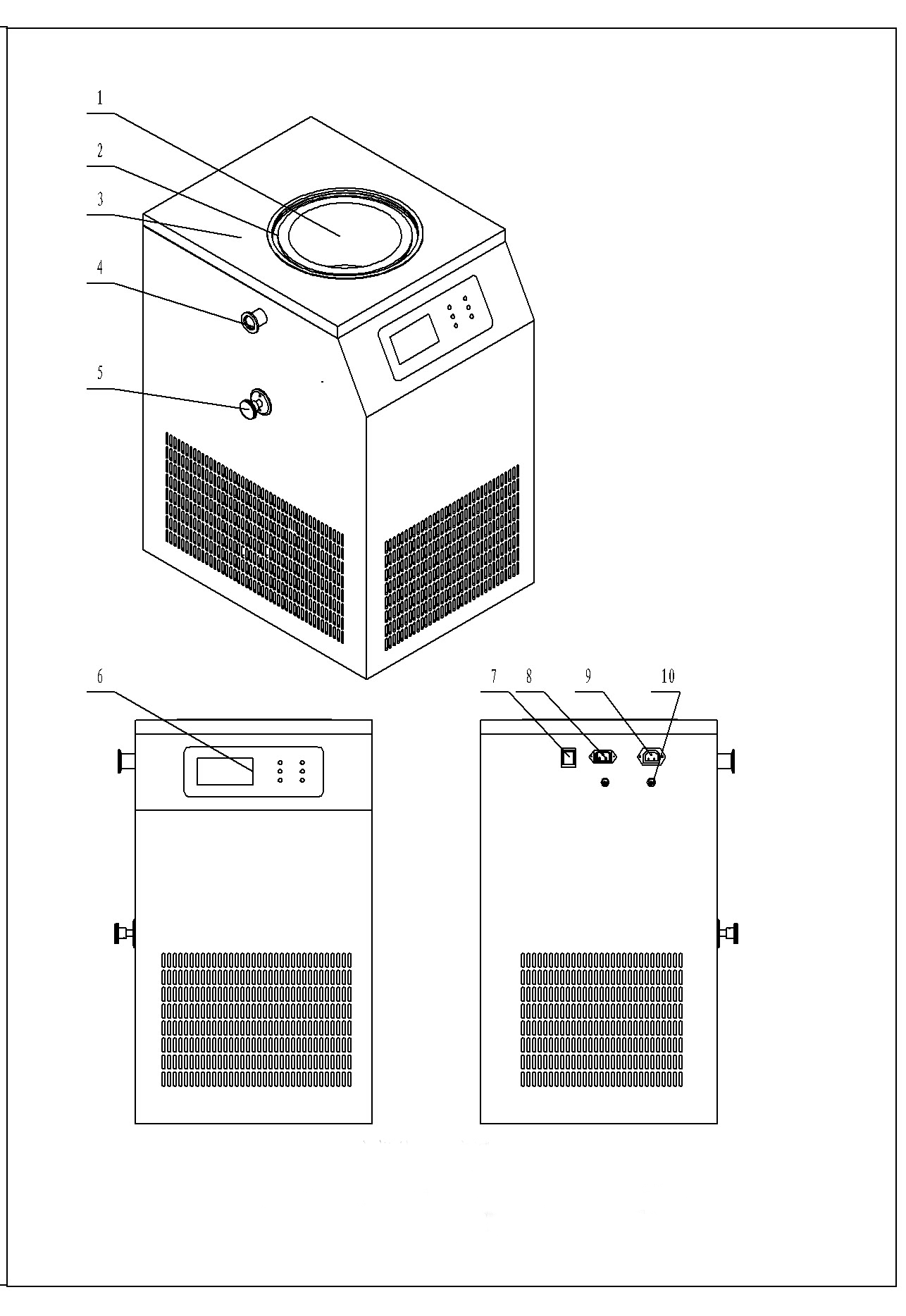

Figure 1

Structure of host

1、condenser

2、sealed ring

3、workbench

4、vacuum port

5、drain valve (air inlet valve)

6、control panel

7、switch

8、general power

9、vacuum pump power

10、fuse

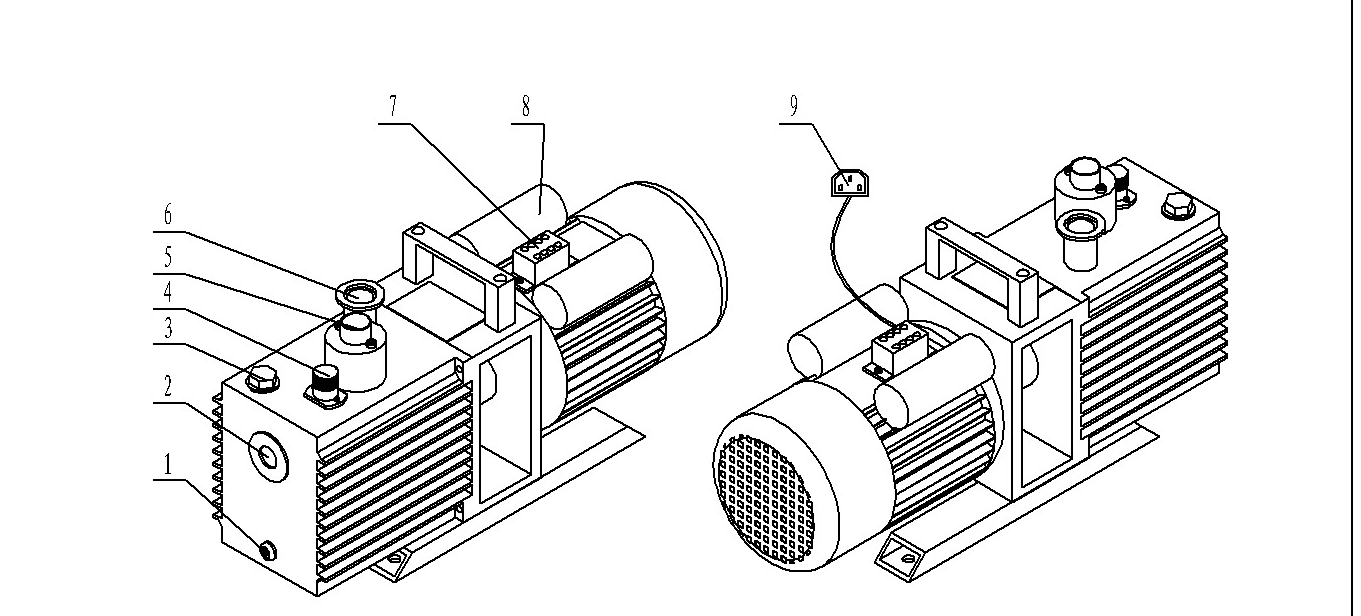

Figure 2

Structure of vacuum pump

1、 oil drain

2、oil level glass

3、 oil filler hole

4、gas ballast valve

5、exhaust port

6、air inlet

7、connecting terminal

8、capacitor

9、vacuum pump power cord

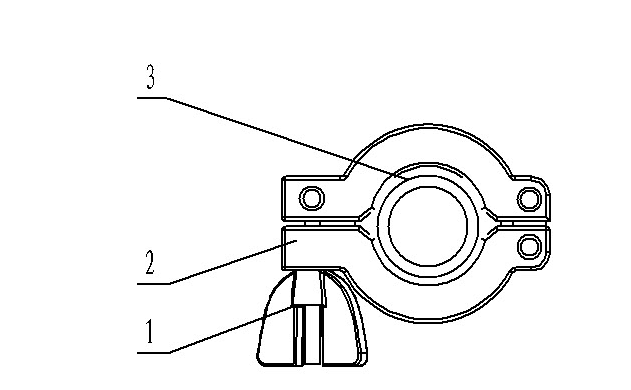

Figure 3

structure of clamp

1、screw nut

2、support

3、 gasket ring

2.Installation of freeze dryer

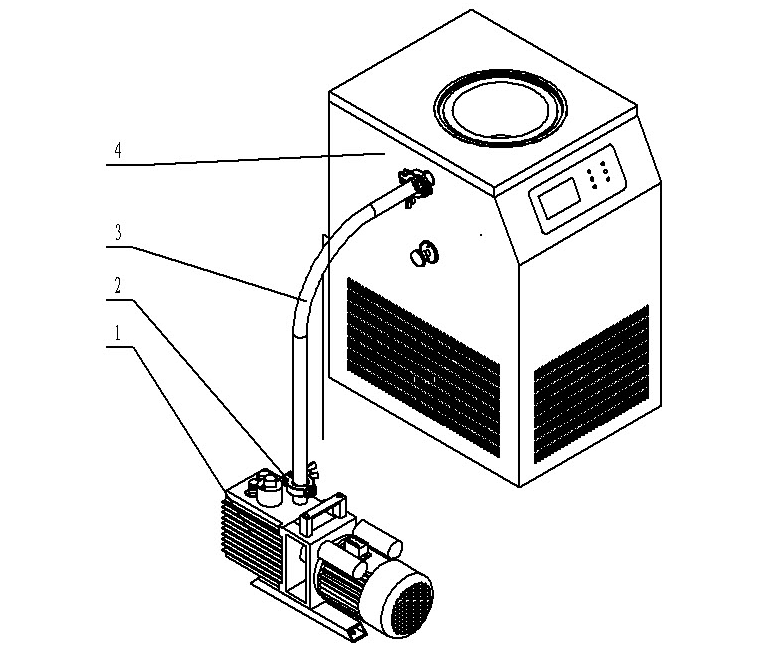

Figure 4

connection of the device

1、 vacuum pump

2、clamp

3、tube that connects host with vacuum pump

4、host

Installation steps:

1) Check accessories complete and undamaged after unpacking box;

2) Add vacuum pump oil to middle of level glass

3) Connect the air inlet on pump and tube by clamp; the other end of tube connected with vacuum port on host;

4) Connect the “vacuum pump power cord” with “vacuum pump power ”interface on host;

5) One end of the power line is inserted into “general power” interface on host; the other end is connected to power supply 220V,50/60Hz (the power should be connected with ground lead)

6) Turn on switch and test the performance of freeze dryer (vacuum degree<10Pa, Minimum condenser temperature<-50℃).Then the device is put into use.

3. Test of freeze dryer

• Test of condenser temperature

1) Cover the pre-freeze lid

2) Turn on switch, to enter control system. Touch the screen, to go to main interface. Press “compressor” to turn on compressor to test refrigeration.

3) Condenser temperature drops to -50℃ within 30 minutes, test is ok.

• Test of vacuum degree

1) Put on sealed ring

2) close the air inlet valve

3) place T-type device on host and close all valves of port

5)Turn on vacuum pump by touching“vacuum pump”. vacuum degree rapidly decline.

6) Vacuum degree goes down below 10 Pa within 20 minutes, test is ok.

7) After finishing tests, open air inlet valve on host and turn off vacuum pump. Then the machine is ready for running.

Notices:

1. There are no obstructions behind and at sides of host within 30cm;

2.Make sure that the vacuum pump oil has been filled before starting up.

5. Operation of pre-freezing and drying process

The general pre-freezing process with steps:User should freeze product in low-temperature freezer. After product is completely frozen , then move to freeze dryer for drying .

Figure 5

Drying process

Drying process with steps:

1 . Take out the frozen product from low temperature freezer;

2. Close the air inlet valve on host;

3. Make sure that sealed ring is placed correctly;

4. Put on T-type manifold ports device

5.Turn on vacuum pump by touching “vacuum pump” button on main interface.The vacuum degree declines. It’s normal that the vacuum degree is less than 20Pa during drying process;

6.Open valve of T-type device port, connect ampoule with port one by one.

7. Drying time is different for material property.

8. When drying process is over, close valve of manifold port, and take off ampoule one by one.

9. First open air inlet valve on host, then turn off vacuum pump by touching “vacuum pump” . Turn off compressor by touching “compressor” button.

10.Close drain valve, machine begins to defrost. After finishing defrosting, open drain valve to drain water. Clean the equipment.

11.When the vacuum pump does not work, please cover the exhaust port to prevent dust.

Notice: a. Compressor can not be turned off in whole freeze drying process;

b. For different materials, freezing time and drying time are not the same ,because of differences in material properties.

6. Turn off machine operation

1 .Turn off power switch;2. Unplug the power cord;

3. Clean condenser, and other parts;

7. Control system operation

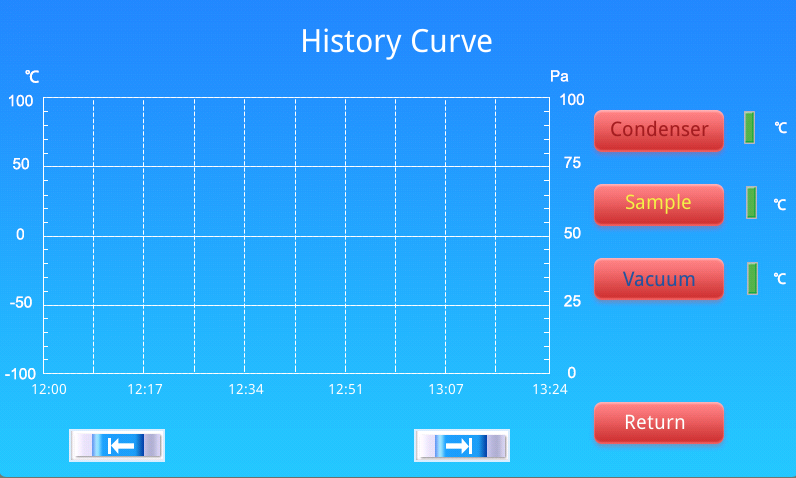

The control system uses LCD touch screen display, easy to operate and the running status is clear. The system displays sample temperature curve, condenser temperature curve and vacuum degree curve. System adopts a variety of stable measures so that control system runs stable and reliable.The control system contains following display screens:

1. Turn on switch, system goes into initial interface. Touch the screen center,

it enters main interface.

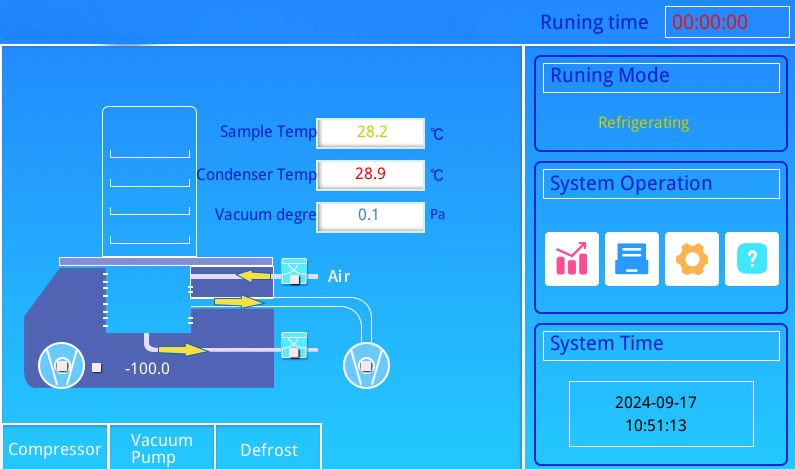

Figure 6

2. Main interface :

Touch“compressor”, compressor starts to work.

Touch“vacuum pump”, vacuum pump starts to work.

Touch “Defrost” , electric defrosting function works.

Figure 7

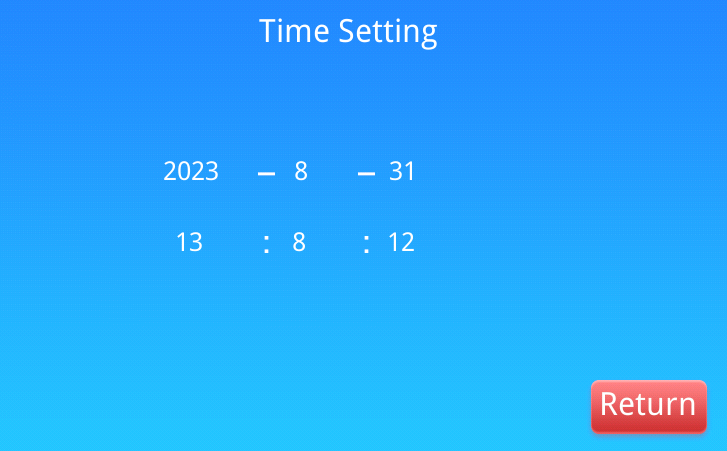

Press on the time display area to access the system time settings, as below picture.

Figure 8

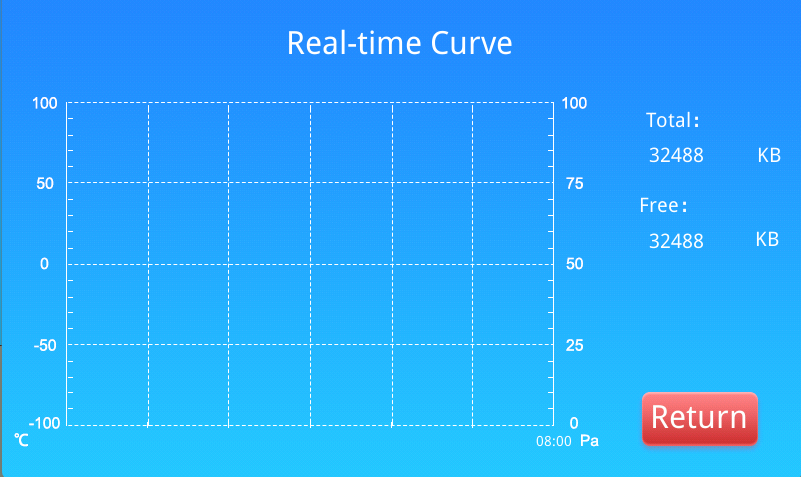

3. Real time curve

Figure 9

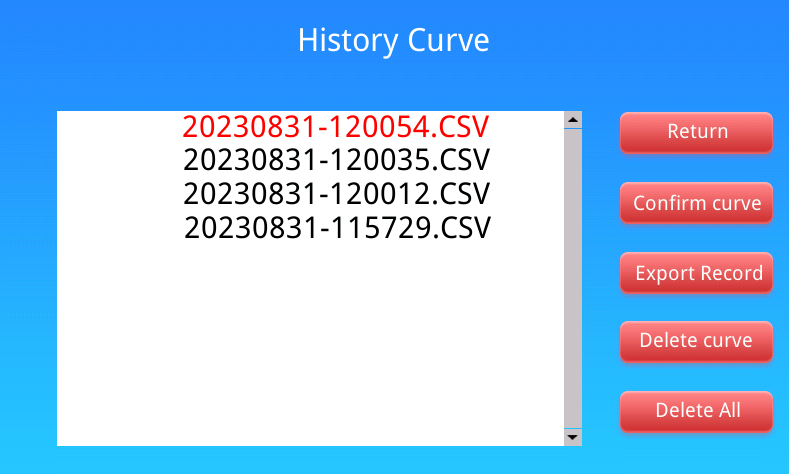

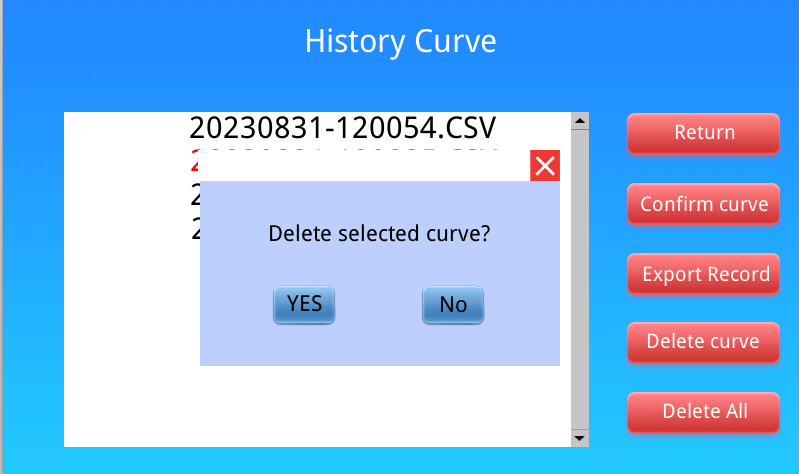

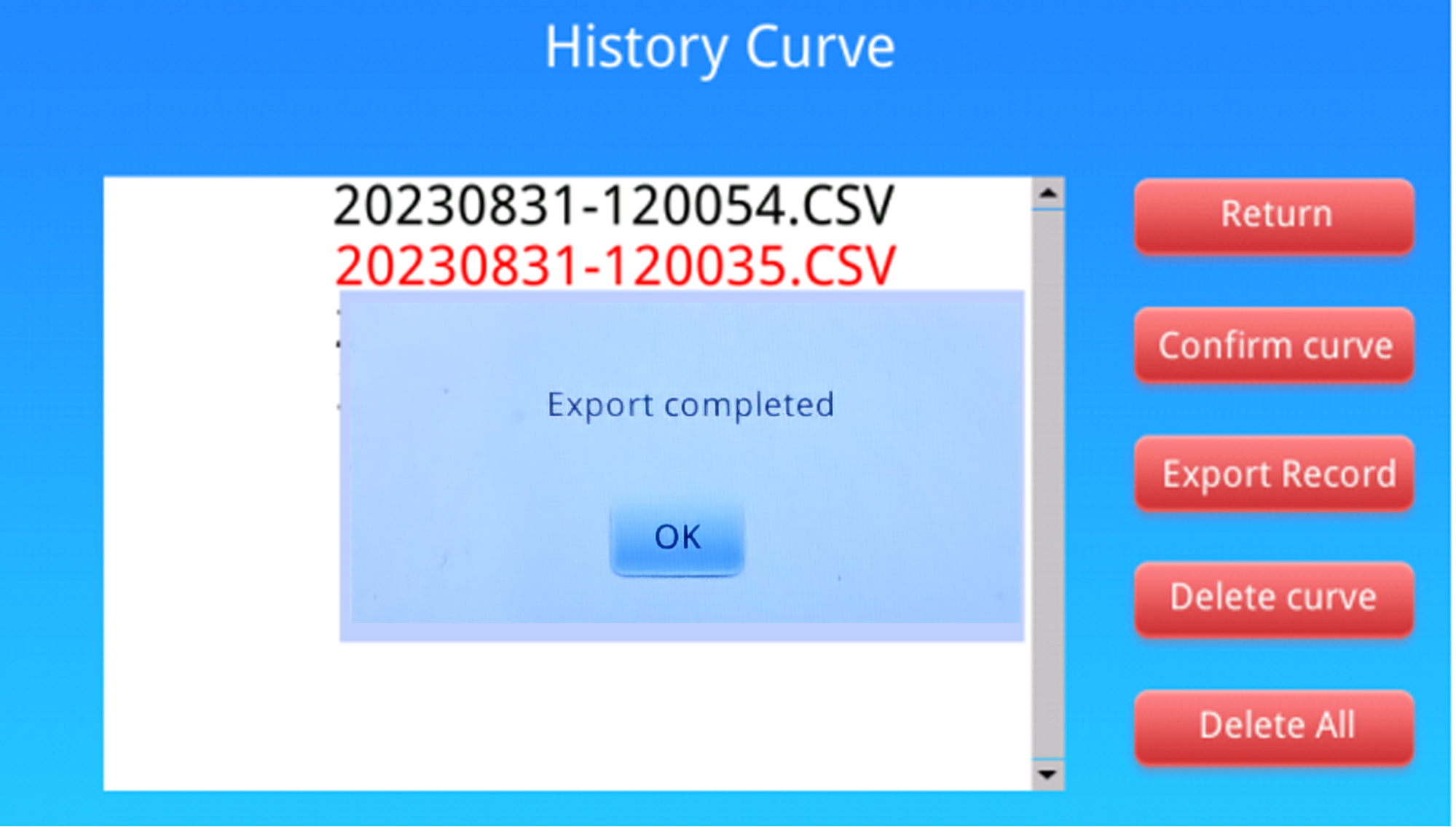

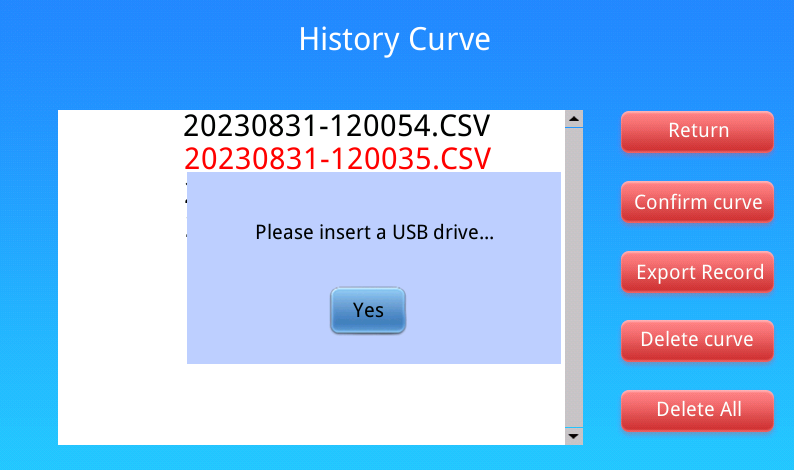

4. History curve and data export

User can check history curve, delete data, export freeze drying data by USB.

Figure 10

Click“Delete curve”, click “YES” to delete selected data.

Figure 11

Click “Delete all” , click “YES” to delete all data.

Figure 12

Insert the USB drive in the USB interface, click “Export Record” .The exported data can

be checked in the “XTDGJ” folder on the USB drive.

Figure 13

An error message will appear if there's an issue with exporting data. Please check the USB connection.

Figure 14

Click“Confirm curve”button , the curve of selected data displays

Figure 15

8. Notices

1.The vacuum pump should be put on ground so that it maintains a certain height difference with host(at least 50cm), to prevent oil return if power is suddenly off. If power off,you should open air inlet valve to inflate the host, take out the samples as soon as possible and properly store samples.2.Working environment temperature should be less than 28℃. Humidity should be ≤70%.

3.When turn off the machine, user should open air inlet valve first, later turn off vacuum pump to prevent oil return and sample pollution.

4.Sealed ring should be kept clean , do not use organic solvent clean;

5.Grounding power socket must be used.

6.The vacuum pump oil should be replaced regularly after working 200 hours continuously.

7.Please don’t frequently turn on and turn off power supply and compressor. If compressor stops working because of wrong operation, user needs to restart the compressor after waiting for at least 3 minutes.

9. Common breakdown and elimination

1.The vacuum degree can not achieve below 15Pa.(1)Check connection between vacuum pump and host, to make sure clamp is tight

(2)Check whether the “O” sealed ring is clean , whether its placement is correct.

(3)Check whether vacuum pump works normally and whether pump oil is clean .

(4)Check whether the air inlet valve is closed tightly

2.High condenser temperature

Ambient temperature is too high , leading to bad heat dissipation. please place the machine in proper environment with well ventilated condition.